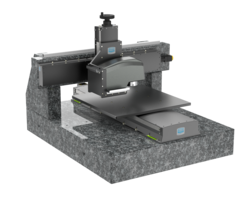

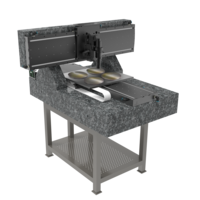

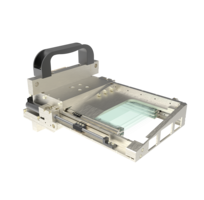

XY theta alignment of UV exposure masks | High-precision positioning system for wafer exposure in a dry nitrogen atmosphere

Handling and Production

786001:002.26

µm Alignment for UV Lithography under extreme process conditions

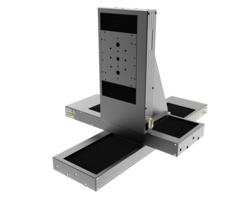

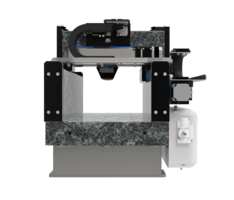

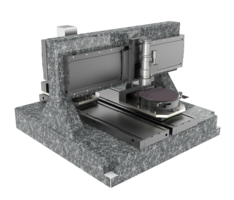

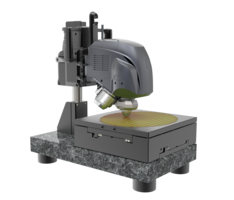

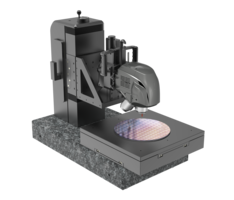

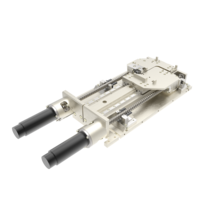

This 3-axis mask positioning system is specifically designed for the ultra-precise alignment of reticles and photomasks in UV lithography. The platform features three linear axes in a parallel-kinematic setup: two in X and one in Y. The two vertical axes generate both vertical lift (same-direction motion) and rotational movement (counter-direction motion). This enables ultra-fine linear and rotational mask positioning in the micro- to nanometer range – even under intense UV exposure and in ultra-dry, oxygen-free N₂ process atmospheres.

High-precision UV Wafer Exposure

|

|

|

|

|

Optionally expandable:

|

Holistic UV-optimized Material and Lubrication Concept

The extreme conditions of UV lithography require highly specialized materials. All relevant structural components are equipped with UV-absorbing or UV-stabilized coatings to minimize stray light. The specialized lubricant used provides exceptional chemical stability under intense UV exposure, features extremely low outgassing, and is thermally as well as chemically resistant to water, acids, bases, and most organic solvents.

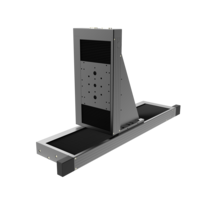

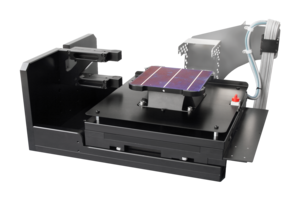

Optimized Maintenance Concept for Lithography Clusters

For maintenance, the system can be moved laterally out of the optical axis into defined service positions. A magnetically preloaded quick-change mechanism enables fast replacement of photomasks with only a few manual steps. Maintenance of motors, initiators, and functional modules is equally simple, as they are designed as exchangeable units.

Customized Extensions and Integration Options

Our engineering services include adapting the system to existing lithography processes, scanner modules, and control architectures. In addition, we develop prototypes and tailor the system to specific process environments, such as particle emission, UV radiation, thermal management, precision manufacturing, working height, collision protection, safety concepts, compensation mechanisms, mask holders, adapters, UV-compatible lubrication, custom colors, pharma-approved motors, as well as comprehensive documentation, test protocols, and lifetime tests.

Application Fields

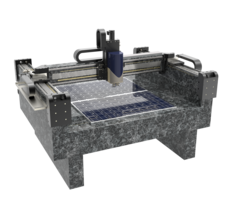

Ultra-precise alignment of photomasks in UV lithography, DUV/ArF processes, electron-beam mask alignment, wafer exposure, chip and die structuring, bonding preparation, PCB and solar cell exposure, as well as high-resolution microstructuring.

| 786001:002.26 | X | Z | Ry | |

| Travel | [µm; deg] | 150 | 50 | ± 1.5 |

Repeatability unidirectional | [µm; deg] | ± 1.5 | ± 2.5 | ± 0.03 |

Repeatability bidirectional | [µm; deg] | ± 2.5 | ± 3.5 | ± 0.05 |

| [mm/s; deg/s] | 25 | 25 | ||

Max. load | [kg] | 3.5 | ||

| Motor | DC-Motor | |||

| Drive | Ball Screw | Ball Screw | Ball Screw | |

| Feedback | Motor-Encoder | Motor-Encoder | Motor-Encoder |

Used Standard Components

KGT 1412 / 1432

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references