In order to offer the optimum solution for your application, we focus on every detail from the very beginning. Our manufacturing techniques lay the foundation for optimum quality and reliability of our components. Besides modern manufacturing technologies we put a great emphasis on the qualification of our employees. Every member of our production staff is trained and specialized for his or her particular work task.

No detail is too small, no challenge too great

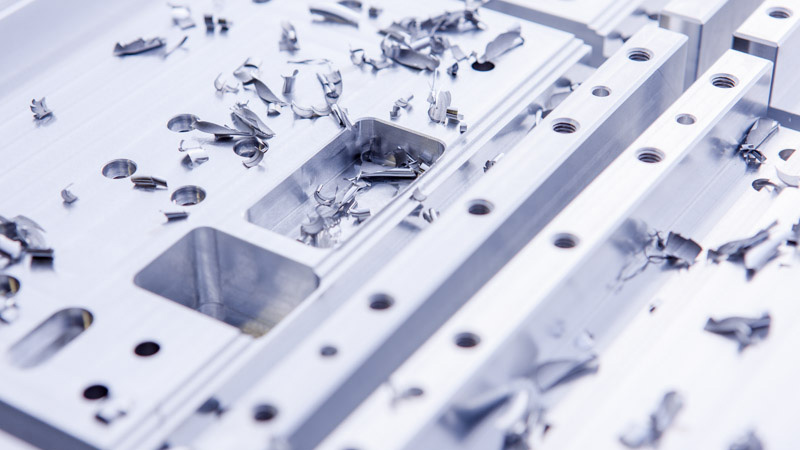

Our broad production portfolio requires utmost flexibility. This is especially true for production. Every day production parts with a volume from 0.5 cm³ to 0.5 m³ are processed on our modern multi-axis machines. Additionally, we offer a large range of different materials ranging from aluminum and stainless steel to titanium. According to the application we decide in cooperation with our customers which material provides the perfect solution.

Straightness and flatness are our benchmark

Often our customers are leading in their technology. This is a benchmark we have to match. Our components meet this challenge. The core competence of Steinmeyer Mechatronik is the processing and grinding of aluminum. Perfect straightness and flatness are only two parameters for the success of many applications. They determine the accuracy of our components and your solution. We attach great importance to an optimum surface quality that will also impress your customers.