Individual and series reproducible measurement results

The testing of your systems will be performed on heavy, vibration-isolated granites, which eliminates the influence of external vibrations and other mechanical disturbances. Measurements are performed with certified and standardized calibrated measuring equipment.

Measurement of your standard systems

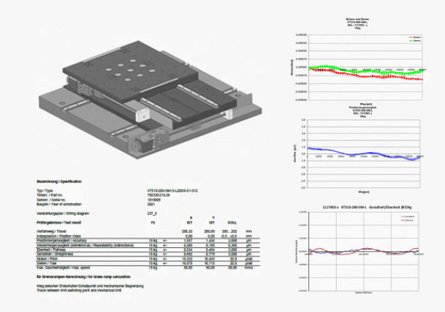

You will receive detailed, written measurement reports for maximum application security. On request, we will provide you with the measured values as a diagram or file.

Our standard measurements include:

- High-precision length values using high-resolution laser interferometers for positioning accuracy and repeatability

- Minimal deviations of form and position tolerances in straightness and flatness via digital fine calipers in a measurement against a certified glass standard

- Angular deviations of rotatory systems by means of mirror polygon and angle measuring system or interferometer

The Steinmeyer Mechatronik quality management system is certified according to DIN EN ISO 9001:2015 as well as DIN EN ISO 50001:2018. Furthermore, we secure and improve the quality standard of our customers with regular customer audits.

Customized measurements Customized to your application, environment and with individual measurement setup | Lifetime tests Determination of the maximum cycles, component wear or for the development of maintenance concepts | Measurement protocols and reports Documented parameters for each series product with protocol, optionally as diagram or file |

Customer-specific measurements and special measurements

The measurement setup can be specially adapted to your application in order to prove the application parameters in the finished system e.g. by means of:

|

|

|

Life cycle tests

Measuring the parameters in the motion profile of the application over its entire lifetime is our specialty.

|

|

|

Measurement protocols and reports

All systems leave us after being measured with standardized measuring equipment such as high-resolution interferometers. For quality assurance each system is traceable:

|

|

|