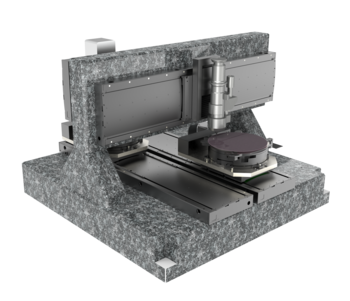

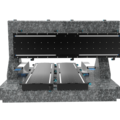

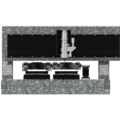

Double XYZ wafer positioner for scanners, microscopes and wafers up to 12 inch / 300 mm (clean room ISO2) | Stroke 720 x 720 x 100 mm

Inspection and Mikroscopy

782430:002.26.oem

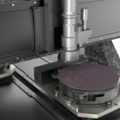

High throughput screening of wafers up to 12"

The inspection system with travel ranges up to 720 mm provides simultaneous high dynamic inspection of multiple 300 mm / 6" wafers. The completely ready-to-use motion system, consisting of the axes, the granite base with gantry, the cable management and the motion controller can be individually configured according to the customer's requirements.

Automated inspection in 3-shift operation

|

|

|

|

Optionally expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired motion control or the completely individual solution development with 3D design for the application-specific positioning task.

Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests.

Fields of application

Wafer and mask inspection up to 12 inch / 300 mm, Metrology, Microscopy, Materials inspection, probe cards and printed circuit boards, AOI, quality assurance, microscopy of large sample, surface inspection, measurement of chips, measurement of complicated geometric shapes

| 782430:002.26 | X | Y | Z | |

| Standard System | PMT290-EDLM | PMT290-EDLM | 0 | |

| Travel | [mm] | 720 | 720 | 100 |

| Repeatability unidirectional | [µm] | ± 0.3 | ± 0.3 | ± 1.5 |

| Repeatability bidirectional | [µm] | ± 0.7 | ± 0.7 | ± 2.5 |

| Positioning speed | [mm/s] | 750 | 750 | 150 |

| Max. speed | [mm/s] | 1500 | 1500 | 300 |

| Max. load | [N] | 150 | 150 | ± 200 |

| Max. sample dimension | [Ø] | 12 inch / 300 mm | ||

| Length x width x height | [mm] | 1230 x 1200 x 1030 | ||

| Drive | Linear Motor | Linear Motor | Servo Motor, Ball Screw | |

| Motor | Ironless Dynamic Linear Motor | Ironless Dynamic Linear Motor | AC Servo | |

| Feedback | Linear Scale | Linear Scale | Motor Encoder | |

| Clean room variants | up to ISO class 2 | |||

| Beam variants | on request | |||

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references