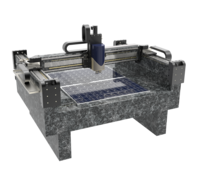

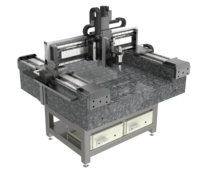

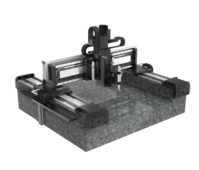

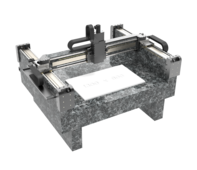

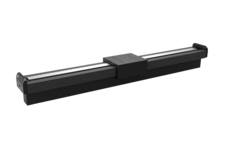

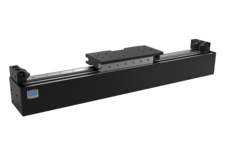

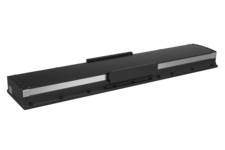

LA250-DLM

Linear Axes

High load stage (linear motor), travel up to 2000 mm, rep ± 0.4 µm, load up to 25 kg, Speed up to 3090 mm/s

Linear axis on granite base for highest demands

This linear axis is designed to precisely positioning of very high loads with particularly long travels of 500 mm up to 2000 mm. The basis of this positioning system is a granite plate, which allows excellent resolution values to be achieved. The drive concept is based on a dynamic linear motor and a linear measuring system, whereby high speeds and accelerations are achieved with high precision and very good reproducibility.

|

|

|

|

|

|

Fields of application

metrology, inspection systems, laser processing, tool measurement, parts measurement, surface inspection, assembly systems, testing systems, quality assurance, pick-and-place systems

| LA250-DLM | -500-DLM-L | -1000-DLM-L | -1500-DLM-L | -2000-DLM-L | |

| Travel | [mm] | 500 | 1000 | 1500 | 2000 |

| Repeatability unidirectional | [μm] | ± 0.4 | ± 0.4 | ± 0.4 | ± 0.4 |

| Repeatability bidirectional | [μm] | ± 0.5 | ± 0.5 | ± 0.5 | ± 0.5 |

| Accuracy | [μm] | ± 2.1 | ± 3.3 | ± 4.5 | ± 5.6 |

| Flatness | [μm] | ± 2.5 | ± 5 | ± 7.5 | ± 10 |

| Straightness | [μm] | ± 2.5 | ± 5 | ± 7.5 | ± 10 |

| Positioning speed | [mm/s] | 790 | 1210 | 1630 | 2060 |

| Max. speed | [mm/s] | 1185 | 1815 | 2445 | 3090 |

| Max. acceleration | [mm/s2] | 16 | 25 | 35 | 40 |

| Max. load Fx | [N] | 250 | 250 | 250 | 250 |

| Max. load Fy | [N] | 3100 | 3100 | 3100 | 3100 |

| Max. load Fz | [N] | 3100 | 3100 | 3100 | 3100 |

| Max. torque Mx | [Nm] | 110 | 110 | 110 | 110 |

| Max. torque My | [Nm] | 150 | 150 | 150 | 150 |

| Max. torque Mz | [Nm] | 150 | 150 | 150 | 150 |

| Pitch | [µrad] | ± 20 | ± 30 | ± 40 | ± 45 |

| Yaw | [µrad] | ± 11 | ± 16 | ± 19 | ± 20 |

| Length | [mm] | 1030 | 1530 | 2030 | 2530 |

| Width | [mm] | 250 | 250 | 250 | 250 |

| Height | [mm] | 160 | 160 | 160 | 160 |

| Weight | [kg] | ± 150 | ± 150 | ± 225 | ± 300 |

| Bearing | Profile Rail | ||||

| Motor | Iron Core Dynamic Linear Motor | ||||

| Feedback | Linear Scale | ||||

| Measuring system resolutions | 0.1 µm (optionally up to 0.001 µm) | ||||

| Material | Anodized Aluminum, Granite | ||||

| Optional features | Frame, custom adapter, bore grid, cable / plugs | ||||

| Variants clean room | up to clean room class ISO 6 (higher on request) | ||||

| Variants beam | UV (DUV, EUV, X-ray, gamma on request) | ||||

| Variants magnetism | magnetic | ||||

| Variants vacuum | on request | ||||

FMC300

Installation module for dynamic applications and high loads and voltage.

PLC

We support integration of our systems into PLC architectures, e.g. Beckhoff

FMC250/280

Multi-axis controller with increased current and voltage for point-to-point positioning.

FMC400/450

Multi-axis controller fully ready for tracking, simple creation of own programs.

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references