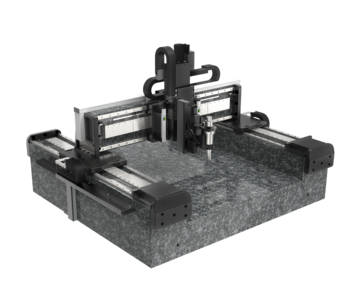

XYZ Gantry System for 3D Automation | XY Linear Motor, Profile Rail | Z Ball Screw, AC Servo | Stroke 700 x 700 x 200 mm

Gantries

782498:001.26

High-precision, universal 3D overhead applications

This 3-axis positioning system can be flexibly adapted to production and inspection processes for various applications. The customized processing or measuring head on the Z-axis moves overhead above the sample carrier. Based on the LA250 linear axis with linear direct drive, this system achieves high speeds and accelerations with high precision and very good reproducibility. For vertical positioning, the high-precision PLT165-AC linear stage with a powerful AC servo motor is used to drive its precision ball screw.

Optimized for powerful automation applications

|

|

|

|

Optionally expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Application areas

Automation, high-dynamic manufacturing processes, micromanufacturing, 3D printing systems, high-resolution inspection of small samples, high-throughput screening, life science microscopy, cytology, diagnostics, laboratory automation, wafer inspection

782498:001.26 |

| X | Y1 | Y2 | Z |

[mm; deg] | 700 | 700 | 700 | 200 | |

Repeatability unidirectional | [µm; deg] | ± 0.2 | ± 0.2 | ± 0.2 | ± 2 |

Repeatability bidirectional | [µm; deg] | ± 0.3 | ± 0.3 | ± 0.3 | ± 2.5 |

[mm/s; deg/s] | 500 | 500 | 500 | 50 | |

Max. load | [N] | 250 | 3100 | 3100 | 1010 |

Motor |

| ||||

Drive |

|

|

|

| |

Feedback |

| Motor-Encoder |

Used Standard Components

LA250-DLM

PLT165-AC

PLT240-AC

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references