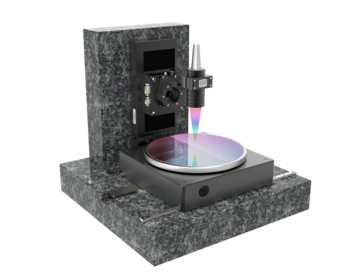

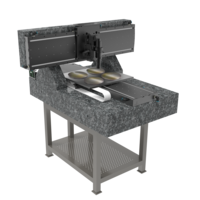

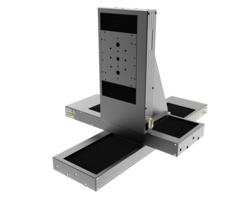

X-Rz-Z-Ry Positioning System for Wafer Inspection up to 12 inch / 300 mm (Cleanroom ISO 6) | Travel 200 mm × n×360° × 100 mm × 60°

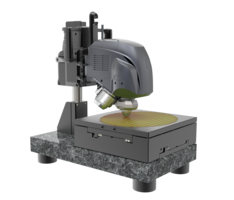

Inspection and Mikroscopy

Art. ID 237790.oem

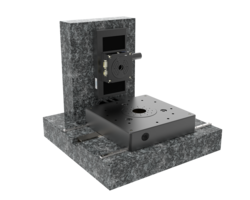

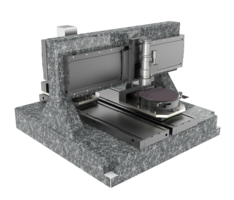

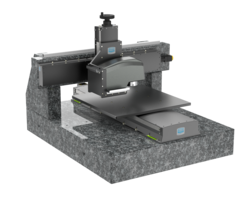

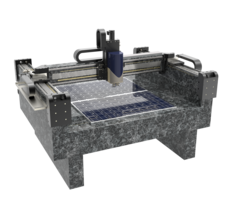

The X-Rz-Z-Ry positioning system is designed for high-precision inspection of 300 mm wafers in cleanroom environments up to ISO Class 6 (better on request). Wafers / chucks are positioned on a combined air bearing rotary and linear system and guided relative to the inspection optics using defined linear, rotational, and tilting motions. The system architecture enables fast scanning motions for high throughput and extremely stable standstill positions for sub-micrometer-accurate measurements - ideal for demanding inspection and metrology processes in semiconductor manufacturing.

High-stiffness inspection with high throughput

|

|

|

|

|

|

Options:

|

Application Fields

Automated wafer inspection up to 300 mm, defect and surface inspection, optical metrology in semiconductor manufacturing, structure and overlay measurements, edge inspection, inspection systems for front-end and back-end processes, inline and offline inspection tools, research and development in semiconductor and microsystems technology

| Art. ID 237790.oem | X | Rz | Z | Ry | |

| Standard system | LA165 | DT350 | PMT160 | DT130 | |

| Travel | [mm; deg] | 200 | n x 360 | 100 | ± 60 |

| Repeatability unidirectional | [µm; deg] | ± 0.3 | ± 0.00018 | ± 0.3 | ± 1.2 |

| Repeatability bidirectional | [µm; deg] | ± 0.4 | ± 0.0003 | ± 0.4 | ± 1.9 |

| Positioning speed | [mm/s; deg/s] | 150 | 410 | 9 | 27 |

| Max. speed | [mm/s; deg/s] | 200 | 620 | 15 | 40 |

| Max. acceleration | [m/s2; deg/s2] | 1.1 | 8500 | 200 | 520 |

| Max. load | [N] | 22 | 15 | ||

| Weight | [kg] | 195 | |||

| Length x width x height | [mm] | 590 x 590 x 550 mm | |||

| Max. sample size | 300 mm / 12 inch | ||||

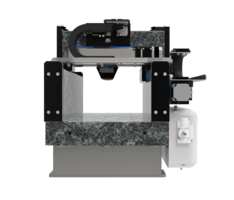

| Motor | Ironless linear motor, torque motor, DC motor | ||||

| Drive | Ball screw, worm gear | ||||

| Guide | Air bearing, cross roller bearing | ||||

| Feedback | Linear scale, angular scale | ||||

| Measuring system resolution | 0.1 µm, optional up to 0.001 µm / none | ||||

| Material | Anodized aluminum, granite | ||||

| Optional features | Design tailored to the customer-specific inspection process, wafer holders, chucks, process head mounting, high-resolution measuring systems for linear and rotary axes, enclosure, frame, safety concepts for use in fab environments | ||||

| Versions for Cleanroom | up to cleanroom class ISO 6 (better on request) | ||||

| Beam variants | UV (DUV, EUV, X-ray, gamma on request) | ||||

| Versions with Lower Magnetism | magnetic | ||||

| Versions for Vacuum | - | ||||

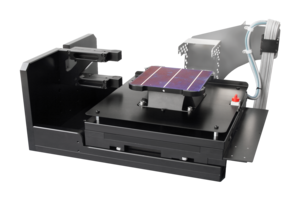

Used Standard Components

DT130-DC

PMT160-EDLM

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references