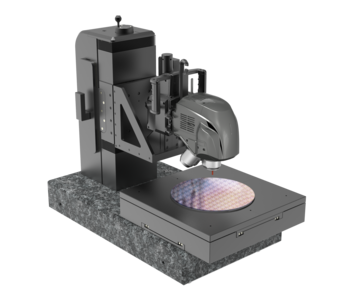

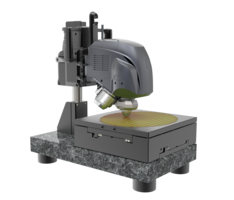

XYZ Positioning System for wafer inspection up to 12 inch / 300 mm (cleanroom ISO 6) | travel 305 x 305 x 200 mm

Inspection and Mikroscopy

782453:030.26.oem

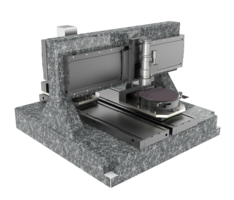

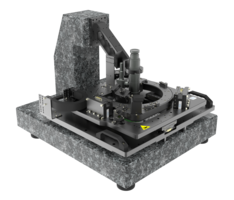

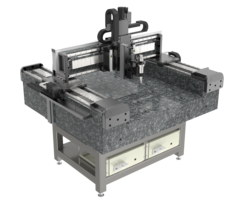

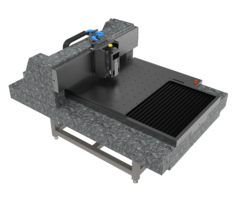

Modular XYZ positioning system for wafer inspection

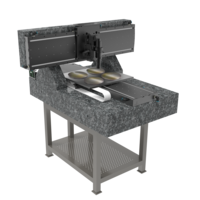

This inspection system consists of the XY-Stage KT470 on a granite structure with a manual Z-vertical unit. This combination is suitable for the flexible and modular design of production systems / inline processes for cleanrooms and can be optionally extended with rotary or motorized Z-axes.

|

|

|

|

Options:

|

Fields of application

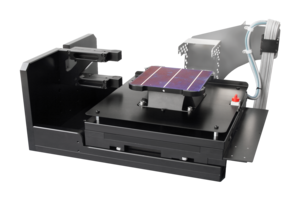

Wafer inspection up to cleanroom ISO 6 (sample size up to 12 inch / 300 x 300 mm), wafer metrology, interferometry and metrology, microscopy, material testing, probecards and printed circuit boards, quality assurance, microscopy in the cleanroom, surface inspection, surface testing, examination of deposits, scratches, irregularities on the surface

| 782453:030.26 | X | Y | Z | |

| Standard System | KT470-SM | KT470-SM | - | |

| Travel | [mm] | 305 | 305 | 200 |

| Repeatability unidirectional | [µm] | ± 2.3 | ± 2.3 | 14,28571429 |

| Repeatability bidirectional | [µm] | ± 3.3 | ± 3.3 | 20 |

| Positioning speed | [mm/s] | 20 | 20 | - |

| Max. speed | [mm/s] | 40 | 40 | - |

| Max. load | [N] | 227 | 227 | 196 |

| Weight | [kg] | 325 | ||

| Max. sample dimension | [Ø] | 12 inch / 300 mm | ||

| Length x width x height | [mm] | 500 x 950 x 740 | ||

| Spindle type | Ball Screw 1214.511/1.12.361.412 P5P / 225177 | Lead Screw | ||

| Spindle lead | 1 | 1 | ||

| Guide | cross roller brearings | cross roller brearings | ||

| Motor | Stepper Motor | Stepper Motor | Handwheel | |

| Feedback | Open Loop | Open Loop | ||

| Optional features | Travels 200 - 350 mm, adaption plate, chuck, base plate (granite / aluminum), frame, housing, custom vibration decoupling by damping rubber pad or pneumatic damper, safety concept and installation (emergency stop, door switch, safety light curtains, laser scanner, STO, SLS) | |||

| Clean room variants | up to clean room class ISO 6 (higher on request) | |||

| Beam variants | UV (DUV, EUV, X-ray, gamma on request) | |||

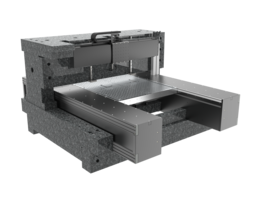

Used Standard Components

KT470-SM

KGT 1214

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references