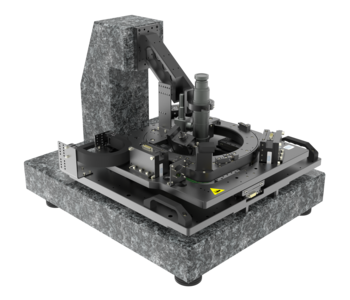

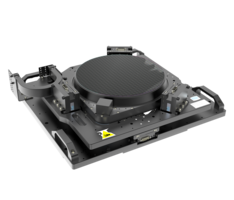

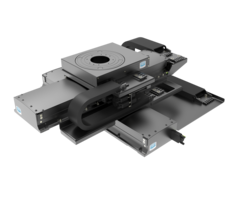

6-axis semiconductor inspection positioning system (clean room class ISO 4) | travel XYZ 30 x 30 x 20 mm, RxRy 4°, Rz 360°

Inspection and Mikroscopy

786015:001.26

6-axis positioning for semiconductors

This 6-axis positioning system provides precise and highly compact alignment of a heavy processing head, e.g. microscope, and the sample. It is mounted directly onto an existing customer-specific machine base (wafer prober). The microscope is attached to a traverse across the aligner. It consists a XY Stage in the horizontal and a tripod for vertical travel and two tilts, and combines the strengths of Cartesian as well as parallel kinematic designs in one system plus continuous rotation on Z.

|

|

|

Options:

|

Fields of application

Semiconductor inspection, MEMS prober testing, alignment, wafer, optics, manipulator, parallel kinematics, testing and bonding on wafers and PCBs, combinations of optical inspection and processing, e.g. for chip-on-board bonding (measuring microscope and laser soldering)

786015:009.26 | X | Y | Z | Rx | Ry | Rz | |

Standard System |

| MT95 | MT95 | 3x MT95 | 3x MT95 | 3x MT95 | |

[mm; deg] | 30 | 30 | 20 | 4 | 4 | 360 x n | |

| Repeatability unidirectional | [µm; deg] | ± 1.5 | ± 1.5 | ± 1.5 | 0.0004 | 0.0004 | 0.05 |

Repeatability bidirectional | [µm; deg] | ± 3.5 | ± 3.5 | ± 3.5 | 0.001 | 0.001 | 0.1 |

[mm/s; deg/s] | 1.1 | 1.1 | 1.1 | 0.3 | 0.3 | 100 | |

| Max. speed | [mm/s; deg/s] | 2 | 2 | 2 | 0.5 | 0.5 | 200 |

Max. load | [N] | 65 | 65 | 100 | 65 | 65 | 20 |

Motor |

|

| Stepper Motor | ||||

Drive |

| Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Belt |

Feedback | Motor-Encoder | Motor-Encoder | Motor-Encoder | Motor-Encoder | Motor-Encoder | - | |

| Aperture diameter | [mm] | 250 (optional larger as special version) | |||||

| Max. sample diameter | [mm] [inch] | 300 12 (450 mm / 18" optional as special version) | |||||

| Length x width x height | [mm] | 720 x 600 x 552 | |||||

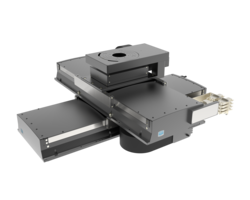

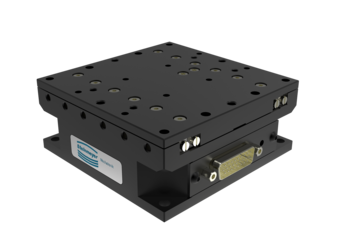

Used Standard Components

MT95-DC

KGT 1214

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references