LA80-2LA95

Vacuum / Cleanroom Multi Axes Systems

782475:053.26, 782475:039.26, 782475:001.26

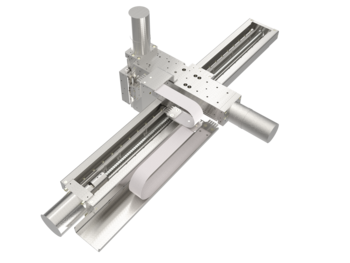

Fast 3-axis UHV system LA80-LA90

UV / UHV / EUV, max. 500 mm travel, 2 µm repeatability, 5 kg load

This fast transfer stage is suitable for precise, fast and long-life applications in ultra-high vacuum. It also meets the requirements for use under extreme ultraviolet radiation due to its very low emission and low particle count. The axes are available in sizes LA80, LA95, LA170 and are designed for loads up to 20 kg in vertical operation. This axis combination was developed as part of the “tOMography Nano crYo (OMNY)” mit dem Paul Scherrer Institut (PSI).

Precise, fast and durable in ultra-high vacuum

|

|

|

|

|

Optionen:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Transport systems in ultra-high vacuum, vacuum applications with dry lubrication, transfer systems, vacuum fine adjustment, EUV lithography, beam shaping for exposure processes, surface analysis, sensor positioning, mass spectrometry, coating processes, coating thickness and coating rate measurements, basic research, laboratory technology, analytics

References

OMNY—A tOMography Nano crYo stage | Review of Scientific Instruments 89, 043706 (2018) | https://doi.org/10.1063/1.5020247

| 782475:001.26 | X | Y | Z | ||||

| Travel | [mm] | 510 | 40 | 80 | |||

| Repeatability unidirectional | [µm] | ± 0.4 | ± 0.4 | ± 0.4 | |||

| Repeatability bidirectional | [µm] | ± 0.5 | ± 0.5 | ± 0.5 | |||

| Positioning speed | [mm/s] | 50 | 4 | 4 | |||

| Max. load | [N] | 30 | 30 | 30 | |||

| Feedback | Linear Scale | Linear Scale | Linear Scale | ||||

| Motor | Stepper Motor | Stepper Motor | Stepper Motor | ||||

| Guide | Cross roller stainless steel, hybrid | ||||||

| Length | [mm] | 706 | |||||

| Width | [mm] | 357 | |||||

| Height | [mm] | 260 | |||||

| Vacuum | [mbar] | up to 10-11 HV/UHV/EUV | |||||

| Lubrication liquid | [mbar] | up to 10-8 | |||||

| Lubrication dry | [mbar] | up to 10-11 | |||||

| Max. bakeout temperature | [deg] | 120 | |||||

| Magnetism Versions | magnetic | low-magnetic | magnet-free | ||||||

FMC 220

Versatile combinable controller, ideal for laboratory applications, control of 1 - 128 axes simultaneously

FMC 250/280

Multi-axis controller with increased current and voltage for point-to-point positioning.

FMC400/450

Multi-axis controller fully ready for tracking, simple creation of own programs.

PLC

We support integration of our systems into PLC architectures, e.g. Beckhoff

Used Standard Components

KGT 1412

201/5000 Even more axes for your vacuum applications:

Even more axes for your vacuum applications?

Almost all atmospheric standard axes are anodized with UHV lubrication for residual pressures up to 10-6 mbar - or even better - available. Click here for the overview of our standard axes!

Dowload our product catalogue: