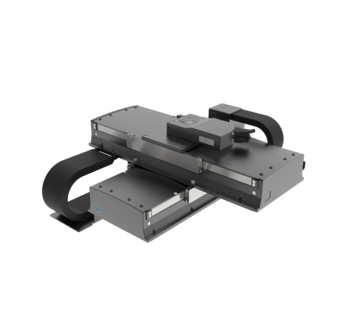

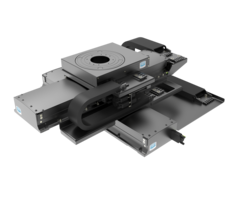

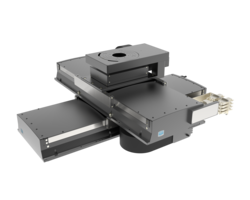

XY-Phi positioning system with 66 mm aperture (clean room) | XY linear motor, profile rail | Phi DC Motor | Travel 200 x 250 mm x 360°

Combinations of industrial axes

782300:097.26

High-precision positioning for samples up to 150 mm / 6"

The system consists of two linear stages PLT240 (X and Y Axes) and a rotary stage DT53, optional DT130 (Phi Axis). Both linear stages are driven by dynamic linear motors, the rotary stage by a DC motor.

|

|

|

|

|

Options:

|

Individual extensions and customizations

The engineering services include the adaptation of the systems to your structure and the desired controls or the completely individual solution finding with 3D design for the application-specific positioning task.

In addition, we develop prototypes and are happy to adapt the systems to the environmental requirements of your application, e.g. particle emission, radiation, temperature, precision special parts production, working height, collision protection, safety concept, compensation factor and filter, sensor holder, brake, decoupling, special lubrication, special colors, holder, adapter, special motors with pharmaceutical approval, extensive documentation, test protocol, lifetime tests

Fields of application

Low-particle linear rotary positioning, e.g. for cutting systems, inspection systems, semiconductor production, wafer dicing & scribing (silicone, GaAs, InP, silica, glass, etc.), optics, photonics, laser technology

| 782300:097.26 | X | Y | Rz | |

| Standard System | PLT240-200-DLM | PLT240-250-DLM | DT58-DC-R | |

| Travel | [mm; deg] | 200 | 250 | n x 360 |

| Repeatability unidirectional | [µm; deg] | ± 0.4 | ± 0.4 | ± 0.004 |

| Repeatability bidirectional | [µm; deg] | ± 0.5 | ± 0.5 | ± 0.007 |

| Positioning speed | [mm/s; deg/s] | 530 | 530 | 100 |

| Max. speed | [mm/s; deg/s] | 1060 | 1060 | 150 |

| Max. load | [N] | 150 | 150 | 150 |

| Weight | [kg] | 60 | ||

| Length x width x height | [mm] | 600 x 650 x 225 | ||

| Max. sample diameter | 150 mm / 6" (optional larger as special version) | |||

| Guide | Profile Rail | Profile Rail | ||

| Motor | Iron Core Dynamic Linear Motor | Iron Core Dynamic Linear Motor | DC Motor | |

| Feedback | Linear Scale | Linear Scale | Motor-Encoder | |

| Optional features | Z-axis (e.g. PMT240) with traverse, linear motor with temperature monitoring, angular scale, adaption plate, chuck, base plate (granite / aluminum), frame, housing, safety concept and installation (emergency stop, door switch, safety light curtains, laser scanner, STO, SLS) | |||

| Clean room variants | up to clean room class ISO 6 (on request) | |||

| Beam variants | UV (DUV, EUV, X-ray, gamma on request) | |||

| Variants magnetism | magnetic | |||

Used Standard Components

PLT240-DLM

DT130-DC

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references