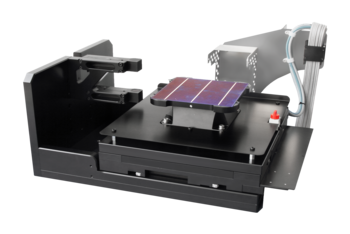

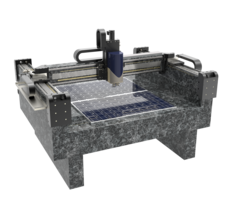

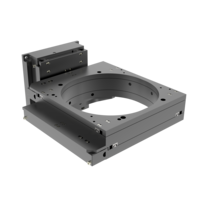

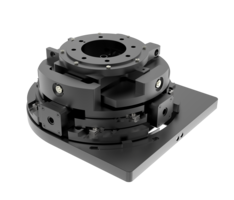

XY-Rz Positioning System for M2 / 6" Wafer Inspection (Cleanroom ISO 6) | XY Linear Motor, Linear Scale | Phi AC Servo, Harmonic Drive | Travel 170 × 170 mm × 360°

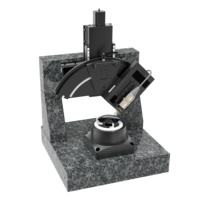

Inspection and Mikroscopy

782460:001.26.oem

Precise Wafer Positioning with Vacuum Chuck

The positioning system moves the wafer via an XY platform with a KT305-EDLM linear stage and an integrated rotary unit (Phi axis). The wafer is fixed by a vacuum chuck and aligned at its edges using a light barrier system. Laser structuring and measurement are then performed.

|

|

|

|

|

|

Options:

|

Custom Extensions and Adaptations

The engineering services include customization for various wafer sizes, sensor types, and control systems. The system can be configured for cleanroom applications, alternative controllers, or specialized vacuum clamping fixtures.

Application Fields

Wafer and mask inspection, solar wafer inspection, laser structuring, microscopy, metrology, quality assurance, automated wafer alignment, semiconductor manufacturing

| 782460:001.26 | X | Y | Rz | |

| Standard System | KT305-edlm | KT305-edlm | DE130-AC | |

| Travel | [mm; deg] | 170 | 170 | n x 360 |

| Repeatability unidirectional | [µm; deg] | ± 0.4 | ± 0.4 | 0.005 |

| Repeatability bidirectional | [µm; deg] | ± 0.5 | ± 0.5 | 0.007 |

| Positioning speed | [mm/s; deg/s] | 50 | 50 | 180 |

| Max. speed | [mm/s; deg/s] | 100 | 100 | 360 |

| Max. load | [N] | 50 | 50 | |

| Dimensions (L × W × H) | [mm] | 515 × 350 × 270 | ||

| Max. sample size | [mm] | 156 × 156 mm / 6" (M2) | ||

| Weight | [kg] | 44 | ||

| Motor | Dynamic Linear Motor (Ironless) | Dynamic Linear Motor (Ironless) | AC Servo (AC) | |

| Drive | Harmonic Drive | |||

| Feedback | Linear Scale | Linear Scale | Motor Encoder | |

| Measurement system resolution | 0.1 µm, optional up to 0.001 µm or better | |||

| Optional features | Alternative linear and rotary stages available, configuration for cleanroom applications, integration of additional sensors or camera systems, customizable software for user-specific alignment algorithms, optional protective covers and vacuum components, adapter plate, chuck, base plate (granite / aluminum), frame, enclosure, customized vibration isolation using damping rubber layers or pneumatic dampers, safety concept and safety technology (emergency stop, door switches, light curtains, laser scanners, STO, SLS) | |||

| Cleanroom versions | up to cleanroom class ISO 6 (higher on request) | |||

| Beam variants | UV (DUV, EUV, X-ray, gamma on request) | |||

| Magnetism variants | magnetic | |||

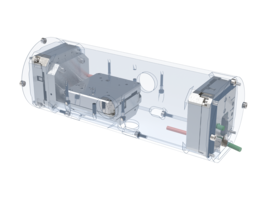

FMC220

Versatile combinable controller, ideal for laboratory applications, control of 1 - 128 axes simultaneously

FMC400/450

Multi-axis controller fully ready for tracking, simple creation of own programs.

PLC

We support integration of our systems into PLC architectures, e.g. Beckhoff

Integrated Controller

We support the integration of the motion controller directly into the positioning system.

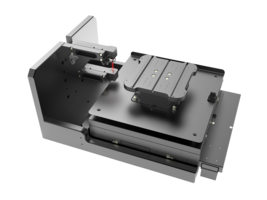

Used Standard Components

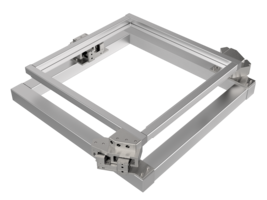

KT305-EDLM

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references