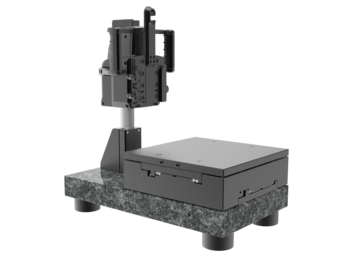

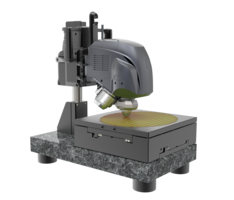

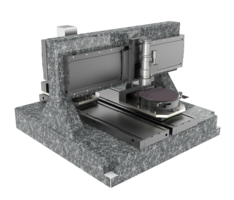

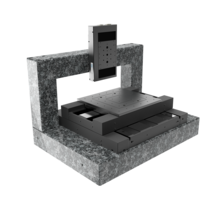

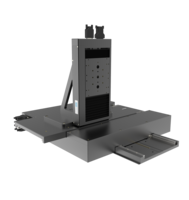

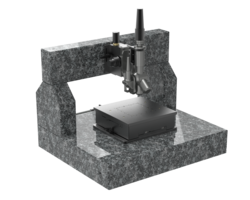

XY-Z Microscopy Stage (ISO 6) | XY stepper motor, ball screw, crossed roller | Z manual | Travel 200 × 200 × M mm, Rep 3 µm, Load 11 kg, Speed 30 mm/s

XY-Z Split Axes Systems

782300:265.26

High-Stability Positioning for Microscopy and Sensor Applications

The positioning system enables highly precise linear motion in X and Y as well as optional Z positioning for accurate alignment of microscopes, cameras, or sensors relative to the sample. While the sensor system remains stationary, the object is moved with high stability and repeatability. This motion task is ideal for imaging, optical, and sensor-based measurement processes where position, focus, and scan location must be precisely controlled.

|

|

|

|

|

Options:

|

Custom Extensions and Adaptations

The system can be specifically adapted to a wide range of optical, biological, or sensor-based measurement tasks. Extensions include dedicated sensor mounts, focus axes, customized control concepts, cleanroom compatibility, temperature or vibration management, as well as mechanical interfaces for customer-specific sample holders or microscope setups.

Application Fields

Semiconductor inspection and wafer microscopy, high-resolution light and fluorescence microscopy, biotechnology and life science, cell and tissue analysis, lab-on-a-chip inspection, microfluidics, material and surface analysis, sensor characterization, optical metrology, research and development

| 782300:265.26 | X | Y | Z | |

| Standard system | KT310-SM | KT310-SM | manual | |

| Travel | [mm] | 200 | 200 | |

| Repeatability unidirectional | [µm] | ± 3 | ± 3 | |

| Repeatability bidirectional | [µm] | ± 5 | ± 5 | |

| Positioning speed | [mm/s] | 30 | 30 | |

| Max. speed | [mm/s] | 60 | 60 | |

| Max. load | [N] | 110 | 110 | |

| With XY Stage | [mm] | 310 | 310 | |

| Dimensions (L × W × H) | [mm] | 550 × 315 × 550 | ||

| Motor | Stepper motor | Stepper motor | ||

| Drive | 1214.590/1.8.245.295 P3P | 1214.590/1.8.245.295 P3P | ||

| Leed | [mm] | 1 | 1 | |

| Bearing | Cross roller bearing | Cross roller bearing | ||

| Feedback | Open Loop | Open Loop | ||

| Optional features | Customizable travels and system dimensions, configuration with or without frame as well as base plate made of granite or aluminum, cleanroom configurations up to ISO class 6 (higher on request), customized cable routing for sensor and camera systems, integration into customer-specific complete systems | |||

| Cleanroom versions | up to cleanroom class ISO 6 (higher on request) | |||

| Beam variants | - | |||

| Magnetism variants | magnetic | |||

| Vacuum variants | on request | |||

Used Standard Components

KT310-SM

KGT 1214

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references