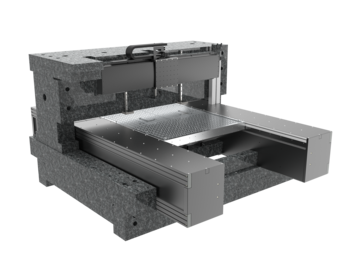

XY laser panel stage with travels up to 2500 x 1500 mm | Positioning system X linear motor, air bearing | Y ball screw, AC servo

Portals

782451:001.26

Air bearing portal system for high loads and long travels

This air bearing XY positioning system is designed for laser processing of large and heavy panels. The customized laser on Z-axis moves extremely fast over the material. Due to the large travels up to 600 mm and an optional extension to 2500 mm, high volumes can be achieved. The same concept can also be used for other highly dynamic and precise applications that require long travels.

Flexible adaptation to different manufacturing requirements

|

|

|

|

|

|

Optionally expandable:

|

High precisely at extreme accelerations

The basis for the system is a solid, stable granite structure. For the x-axis with 1600 mm travel, preloaded air bearings are used to achieve a flatness of travel < 1 µm over 100 mm. In addition, the air bearings eliminate all wear, despite the very high cycles typical of industrial applications. The Y-axis consists of a cost-optimized and industry-proven linear stage model PMT320 with 1150 mm travel.By using Tecnotion servo linear motors in both axes, accelerations up to 5 G and speeds of over 120 m/min can be achieved. The integrated linear encoders enable a position resolution of 0.1 µm. A standard ball screw drive is used for the vertical movement of the laser.

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Application areas

Laser processing, laser structuring, thin film solar panel processing, laser micromachining, microsuction, flat panel manufacturing, high speed applications

782451:001.26 | X | Y | |

[mm; deg] | 1600 | 1150 | |

Repeatability unidirectional | [µm; deg] | ± 0.3 | ± 0.4 |

Repeatability bidirectional | [µm; deg] | ± 0.4 | ± 0.5 |

Positioniergeschwindigkeit | [mm/s; deg/s] | 1630 | 1210 |

Max. load | [N] | 100 | 3100 |

Motor |

| ||

Führung | Profile Rail | ||

Feedback |

Used Standard Components

PLT320-DLM

LA340-EDLM

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references