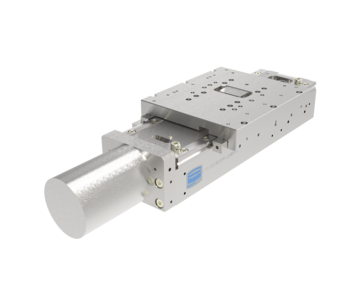

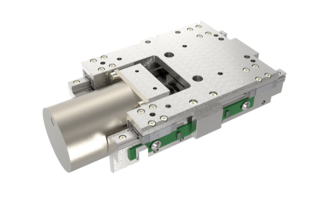

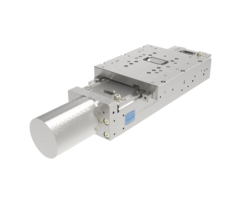

LA95

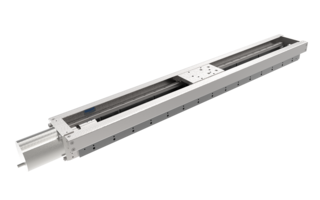

Vacuum / Cleanroom linear stages and axes

782475:055.26 (40); 782475:054.26 (80), 782475:016.26 (185) - with gear box

Precision linear stage

HV 10E-9 mbar, EUV, ISO 4 | Travel 10 – 185 mm | Rep 0.4 µm | Load 4.5 kg | Speed 8.4 mm/s

|

|

|

Options:

|

Fields of application

Positioning for scanning applications, micro-assembly, semiconductor technology, ultra-high vacuum, vacuum chambers, research, beamline instrumentation, electronics assembly and inspection, positioning system for laboratory inspection

| LA95 | -40-SM | -40-SM-L | -80-SM | -80-SM-L | -185-SM | -185-SM-L | |

| Travel | [mm] | 40 | 40 | 80 | 80 | 185 | 185 |

| Repeatability unidirectional | [μm] | ± 1.9 | ± 0.4 | ± 1.9 | ± 0.4 | ± 1.9 | ± 0.4 |

| Repeatability bidirectional | [μm] | ± 2.9 | ± 0.5 | ± 2.9 | ± 0.5 | ± 2.9 | ± 0.5 |

| Positioning speed | [mm/s] | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 |

| Max. speed | [mm/s] | 8.4 | 8.4 | 8.4 | 8.4 | 8.4 | 8.4 |

| Max. load Fx | [N] | 45 | 45 | 45 | 45 | 45 | 45 |

| Max. load Fy | [N] | 40 | 40 | 40 | 40 | 40 | 40 |

| Max. load Fz | [N] | 40 | 40 | 40 | 40 | 40 | 40 |

| Length (with gear box) | [mm] | 260 | 260 | 285 | 285 | 410 | 410 |

| Length (without gear box) | [mm] | 235 | 235 | 260 | 260 | 385 | |

| Width | [mm] | 105 | 105 | 105 | 105 | 95 | 95 |

| Height | [mm] | 50 | 50 | 50 | 50 | 55 | 55 |

| Weight | [kg] | 2.6 | 2.6 | 4.5 | 4.5 | ||

| Max. Bakeout temperature | [deg] | 120 | |||||

| Lubrication liquid | [mbar] | up to 10-8 | |||||

| Lubrication dry | [mbar] | up to 10-9 | |||||

| Drive | Lead Screw TR8x1.5 | ||||||

| Motor | Stepper Motor | ||||||

| Bearing | cross roller bearings stainless steel, hybrid | ||||||

| Feedback | Open Loop | Linear Scale | Open Loop | Linear Scale | Open Loop | Linear Scale | |

| Resolution Measuring system | 0.1 µm, optional up to 0.01 µm | 0.1 µm, optional up to 0.01 µm | 0.1 µm, optional up to 0.01 µm | ||||

| Optional features | Gear box, lead screw with dry lube or ball screw with liquid lube, custom fluorine-free / PFAS-free UHV lubrication, adapter, bore grid, cable / plugs | ||||||

| Variants clean room | up to clean room class ISO 4 (higher on request) | ||||||

| Variants beam | UV, DUV, EUV (X-ray, gamma on request) | ||||||

| Variants Magnetism | magnetic | ||||||

| Variants vacuum | all ranges up to 10E-9 mbar HV | ||||||

Related Products

201/5000 Even more axes for your vacuum applications

Almost all atmospheric standard axes are anodized with UHV lubrication for residual pressures up to 10E-6 mbar - or even better - available. Click here for the overview of our standard axes!

Overwiew standard stages Contact technical consultants

Only selected materials, components, and lubricants meet the requirements for low outgassing. In many cases, the use of liquid lubricants is not possible. In addition, the bake-out process places significant stress on the positioning system; thermal stresses occurring at temperatures of up to 140 °C must be taken into account.

All components are designed to be vacuum-compatible and are specially cleaned after manufacturing. Assembly is carried out under cleanroom conditions. For non-magnetic systems, the choice of materials is even more severely restricted.

We offer a wide range of solutions for both UHV systems with the highest performance requirements and non-magnetic assemblies.

The customized adaptation of our positioning systems to existing chambers or setups is carried out in several structured steps. The goal is seamless integration with maximum precision, cleanroom and/or vacuum compatibility, and operational reliability.

Typically, the customization process includes:

- Analysis of the installation situation (available space, interfaces, loads, degrees of freedom, environmental conditions)

- Application-specific alignment with respect to vacuum, cleanroom, magnetism, or radiation requirements

- Mechanical adaptations such as custom adapters, base plates, hole patterns, or installation heights

- Adaptation of drive, measurement, and cabling concepts, including connector routing, feedthroughs, and cable management

- Material and lubricant selection tailored to outgassing behavior, particle requirements, and bake-out conditions

The system design is carried out using 3D design and simulation, optionally complemented by prototypes, functional testing, and cleanroom or vacuum preparation.

Our positioning systems are designed for various cleanroom classes in accordance with ISO 14644-1 and can be adapted to the specific application. As standard, we implement systems for ISO 6 to ISO 4. For particularly demanding custom applications—depending on system concept, motion, materials, and lubrication—cleanroom classes down to ISO 2–1 are also possible.

The achievable cleanroom class depends, among other factors, on:

- the selected mechanics and bearing concept

- the drive and measurement systems used

- materials, surface treatments, and lubricants

- motion profiles and operating conditions, e.g., enclosure and extraction

- multi-level cleaning processes, handling, and commissioning

All cleanroom systems are appropriately prepared, assembled, and final-cleaned in a cleanroom environment. Upon request, we develop custom solutions precisely tailored to the required cleanroom class and application.

Nearly all atmospheric standard axes are available anodized with UHV lubrication for residual pressures down to 10E-6 mbar — or even better. For systems with stepper or piezo motors, we offer the following vacuum preparation:

- All parts vacuum-cleaned

- Liquid lubrication with UHV oil for pressures down to 10-6 mbar

- Maximum bake-out temperature 80 °C

- Equipped with Phytron stepper motors

- Stainless steel components (ball screw, guides, bearings, screws)

- Kapton or PTFE cabling

- Kapton or ceramic Sub-D connectors

- Untreated aluminum surfaces

- Bores and cavities with venting holes, vented screws, or slotted washers

- No covers

- Assembled in our cleanroom

- Final cleaned

- Delivered in evacuated, double plastic packaging

Click here for more systems:

Overview of our standard axes

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail