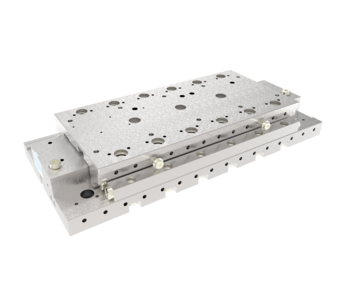

LA92

Vacuum / Cleanroom linear stages and axes

782475:037.26, 782475:028.26

High Speed Stage

UHV 10E-11 mbar, EUV, ISO 4 | Travel 40 mm | Rep 0.4 µm | Speed 150 mm/s

|

|

|

|

Optionally configurable:

|

Fast horizontal and vertical positioning in UHV

The linear axis is mainly used for scanning samples. It allows fast positioning with extremely high resolution in ultra-high vacuum, also in vertical direction. It has a very narrow design with internal motors.

Application areas

High resolution and fast scanning applications, micro assembly, semiconductor technology in ultra-high vacuum, vacuum chambers, research, beamline instrumentation, electronics assembly and inspection.

| LA92 | -40-LM-L | ||

| Travel | [mm] | 40 | |

| Repeatability unidirectional | [μm] | ± 0.3 | |

| Repeatability bidirectional | [μm] | ± 0.4 | |

| Positioning speed | [mm/s] | 100 | |

| Max. speed | [mm/s] | 150 | |

| Max. load Fx | [N] | 19 | |

| Max. load Fy | [N] | 19 | |

| Max. load Fz | [N] | 9 | |

| Length | [mm] | 205 | |

| Width | [mm] | 92 | |

| Height | [mm] | 32 | |

| Lubrication liquid | [mbar] | up to 10-8 | |

| Lubrication dry | [mbar] | up to 10-11 | |

| Max. Bakeout temperature | [deg] | 120 | |

| Motor | Nanomotion | ||

| Bearing | cross roller bearings stainless steel, hybrid, optional full ceramic | ||

| Feedback | Linear Scale | ||

| Resolution Measuring system | 0.1 µm, optionally up to 0.005 µm | ||

| Optional features | custom fluorine-free / PFAS-free UHV lubrication, adapter, bore grid, cable / plugs | ||

| Variants clean room | up to clean room class ISO 4 (higher on request) | ||

| Variants beam | UV, DUV (EUV, X-ray, gamma on request) | ||

| Variants Magnetism | magnetic, low-magnetic, magnet-free | ||

| Variants vacuum | all ranges up to 10-11 mbar HV / UHV | ||

201/5000 Even more axes for your vacuum applications

Almost all atmospheric standard axes are anodized with UHV lubrication for residual pressures up to 10-6 mbar - or even better - available. Click here for the overview of our standard axes!

Overwiew standard stages Contact technical consultants

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail