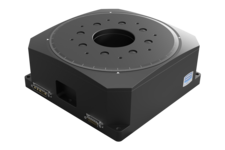

DT200-SM

Rotary Stages

Flat rotary stage (SM motor), travel n × 360°, aperture ⌀ 66 mm, repeatability ±0.008°, load capacity 11 kg, speed 41°/s

Flat precision rotary stage

The DT200-SM is a compact rotary stage with a height of only 40 mm and a rotation range of n × 360°. The stage achieves high accuracy and repeatability thanks to its thin-section bearing, precise belt/gear drive, and motor encoder feedback. With a 170 mm turntable and a 66 mm aperture, the stage is ideally suited for precise angular positioning in metrology and optical applications.

|

|

|

|

Options:

|

Custom Extensions and Adaptations

The DT200-SM can be used as a single axis or flexibly combined into multi-axis positioning systems — particularly with linear stages of the PMT160 series or the HT160 lift stage. Adaptations include alternative motor configurations, special surface coatings, customized rotary feedthroughs, or optimized interfaces for measurement systems.

Application Fields

Metrology, optical and laser technology, test stands, laboratory analytics, research & development, experimental physics, automated scanning processes, precision positioning of sensors, optics, or samples

| DT200-SM | -SM | |

| Travel | [deg] | n × 360 |

| Repeatability unidirectional | [deg] | ± 0.008 |

| Repeatability bidirectional | [deg] | ± 0.016 |

| Positioning accuracy | [deg] | ± 0.017 |

| Excentric runout | [µm] | ± 4 |

| Wobble | [µrad] | ± 25 |

| Positioning speed | [deg/s] | 27 |

| Max. speed | [deg/s] | 41 |

| Max. acceleration | [deg/s²] | 461 |

| Max. load Fz | [N] | 110 |

| Max. torque Mx, My | [Nm] | 16.6 |

| Max. torque Mz | [Nm] | 8.3 |

| Length | [mm] | 240 |

| Width | [mm] | 200 |

| Height | [mm] | 40 |

| Turntable Ø | [mm] | 170 |

| Aperture Ø | [mm] | 66 |

| Weight | [kg] | 4.0 |

| Bearing | Thin-section bearing | |

| Motor | Stepper motor (SM) | |

| Drive | Belt, Gear Box | |

| Feedback | Motor encoder | |

| Surface | Anodized aluminum, Nickel | |

| Optional features | DC or stepper motor, electrical or pneumatic rotary feedthrough, precision-ground plate for optimized flatness, brake, rotation limit, cable guidance, wrap-around hard stop, purge air, extraction | |

| Cleanroom versions | ISO 4 (higher on request) | |

| Beam variants | EUV, DUV, UV (X-ray and gamma on request) | |

| Magnetism variants | - | |

| Vacuum variants | - |

Related Products

Nearly all atmospheric standard rotary stages shown here are optionally available in a non-anodized version with UHV-compatible lubrication for residual pressures up to 10E-6 mbar. In this configuration, they achieve at least cleanroom class ISO 6 - or better - making them suitable for demanding environments.

For higher requirements, specially designed rotary stage variants are available, for example for cleanroom class ISO 2, vacuum up to 10E-11 mbar, or harsh radiation environments.

The vacuum rotary stages are specifically engineered for high axial and radial loads. Reinforced bearing concepts, adapted material selection, and vacuum-compatible lubrication and coating systems ensure stable rotation even under high payloads and large moments of inertia.

Overview Cleanroom & Vacuum Rotary Stages Contact Technical Consulting

Materials for Rotary Stages

Steinmeyer Mechatronik primarily uses aluminum for the structural components of rotary stages. This material provides an optimal balance of weight, stiffness, and thermal conductivity—critical for precise runout and repeatability.

Aluminum efficiently dissipates localized heat, for example from motor losses or bearing friction. As a result, the rotary stage quickly reaches a thermally stable condition—an essential prerequisite for consistent angular accuracy during continuous operation or high-dynamic motion.

The lower stiffness of aluminum compared to steel is compensated by design measures, such as:

- Reinforced housing and bearing structures

- Optimized wall thicknesses and installation heights

- Hollow profile constructions with high torsional stiffness

For special requirements—such as high load capacities, vacuum-compatible designs, or magnetically sensitive applications—steel or titanium versions are available as alternatives.

Functional Surfaces and Coatings for Rotary Stages

In addition to standard finishes, numerous customized surface and coating concepts are available. These are specifically designed to achieve very high cleanroom classes—up to ISO 1–2, depending on the application and process.

To meet demanding process requirements, we develop and qualify application-specific functional coatings, including:

- Nickel coatings

- PTFE & KEPLA® coatings

- Fluorinated lubricants

- Dicronite® / dry-film coatings

- Application-specific coating combinations

The following surface options are also available:

- Anodized (cleaned)

- Alternative anodized colors

- Aluminum bare, cleaned

- Bilatal

- Nickel

These surfaces are particularly suitable for:

- High cleanliness requirements in cleanroom environments

- Vacuum applications

- Chemically aggressive environments (e.g., life sciences)

- Optical systems with stray light requirements

Why Functional Coatings Are Critical for Rotary Stages (Before → After)

- Standard surface → EUV-compatible surface

- Reflective → Non-reflective, minimized stray light

- Standard sliding behavior → Optimized friction coefficients & reduced wear

- Basic protection → Enhanced chemical & corrosion resistance

- Standard configuration → Application-optimized performance

Special surface treatments are often required for UV / DUV / EUV applications (X-ray or gamma applications available upon request).

Yes. Our rotary stages can be modularly combined with linear, XY, or XYZ stages to form compact multi-axis systems (e.g., XYZ-R or Theta-Z). The required mechanical interfaces are already integrated into the design.

Typical Configurations

- XY + R → Compact rotation and positioning systems

- XYZ + R → 4DOF positioning

- Theta-Z → Combined rotational and vertical motion

- Parallel kinematic structures → For active alignment applications

Advantages of the Combination

- High system flexibility

- Modular expandability

- Space-saving integration

- Precise coordination of rotation and translation

Technical Requirements

- Matched mechanical interfaces (mounting pattern / centering)

- Rotary stage load capacity designed for additional axes (Fx, Fy, Fz)

- Consideration of moment of inertia and center of gravity

- Synchronized control of all axes

We are happy to advise you—quickly and without obligation:

For rotary stages, Steinmeyer offers standard motion controllers, PLC integration, as well as custom embedded solutions. Depending on torque requirements, dynamic performance, and installation constraints, the controller can be implemented externally in a control cabinet or fully integrated into the rotary stage module.

Overview Motion Controllers & Control Concepts

System Architecture – Optimized for Rotary Axes

Control solutions for rotary stages are selected application-specifically and precisely matched to the drive concept (e.g., torque direct drive or geared drive), angular measurement system, and environmental conditions. Particular focus is placed on runout accuracy, axis synchronization, and thermal stability.

Standard Motion Controllers

- For single rotary stages or rotational multi-axis systems (e.g., XYZ-R)

- Configurable control loops (position / speed / torque)

- High-resolution angular feedback

- Fieldbus interfaces (e.g., EtherCAT, PROFINET)

- Fast commissioning and fine-tuning

Typical application: Precision rotary stages with torque motor, direct drive, or gear-based rotation.

PLC Integration

- Integration into existing machine or system control architectures

- Centralized system logic via customer PLC

- Synchronization with linear axes or gantry systems

- Standardized industrial communication protocols

Typical application: OEM equipment, inspection systems, semiconductor tools, or assembly systems.

Custom Embedded Solutions

- Compact, application-optimized controllers for rotary stage modules

- Integrated power stages for torque or servo motors

- Reduced cabling effort

- Optimized for cleanroom, vacuum, or high-dynamic applications

Typical application: Highly integrated rotational systems with limited installation space or increased requirements for dynamics and precision.

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references