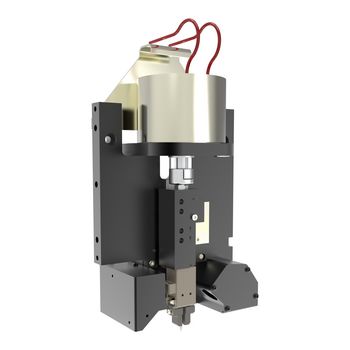

3D contact printhead for highly dynamic applications (clean room) | High-precision and viscosity-independent printing of various materials

Additive manufacturing / 3D Printing

782420:004.26

Fast short movements with high precision in the vertical

This high-precision positioning system is specially designed for cost-effective contact 3D printing processes. The print head is actuated by a voice coil so that during the printing process the sample is positioned highly dynamically and precisely with minimal distance to the carrier. Thus, the smallest media can be positioned on carriers with extremely fast movements, independent of viscosity, with high precision and without damaging them. A linear measuring system in an almost Abbé arrangement enables repeatability of 1 µm and better if required.

Highly precise and viscosity-independent 3D printing

|

|

|

|

|

Optionally expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

3D printing of biological and synthetic materials, additive manufacturing of tablets and drugs, chip systems, automation in chip manufacturing, digital printing

| 782420:004.26 | Z | |

| Lift | [mm; deg] | 10 |

| Repeatability unidirectional | [µm; deg] | ± 0.6 |

| Repeatability bidirectional | [µm; deg] | ± 1 |

| Positioning speed | [mm/s; deg/s] | 25 |

| Motor | DC-Motor | |

| Drive | Voice Coil |

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references