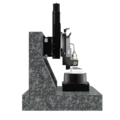

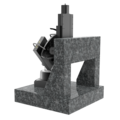

Rz-X-Y-Ry-Rx | Z-R-F 8-axis positioner for inspection of optics | aperture rotary stage and aligner 45 mm | stroke 360°, 2 x 2 x 25 mm, 90°, 50 mm

XYZ Tip-Tilt System

417815.2022.W3.AB

8-axis adjustment for various inspection angles

This positioning system allows tangential scanning in 6 degrees of freedom with a very high repeatability. The sample holder, which is adjustable in focus, angle and distance, is located on an XYZ phi delta aligner with aperture, which corrects for tilt and lateral offset in 4 axes. Combined with the aperture rotary stage below, additional 360° rotations and incident and transmitted light measurements are possible. A very stiff vertical stroke support a manual angle adjustment with motorized distance adjustment for the sensor, which also operates as a focus.

Ideal for 2D transmission measurements

|

|

|

|

Options:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired motion control or the completely

417815.2022.W3.AB |

| Rz sample | X sample | Y sample | Rx sample | Ry sample | R sensor | F sensor | Z sensor | |

Standard System |

| DT250 | MP200-5 | MP200-5 | MP200-5 | MP200-5 |

| PMT160-DC-L | PLT165-SM | |

[mm; deg] | n x 360 | ± 2 | ± 2 | ± 1.5 | ± 1.5 | 90 | 50 | 100 | ||

Repeatability unidirectional | [µm; deg] | 0.0005 | ± 0.5 | ± 0.5 | ± 1.3 | ± 1.3 | 1 | ± 0.3 | ± 3.9 | |

Repeatability bidirectional | [µm; deg] | 0.001 | ± 2 | ± 2 | ± 5.2 | ± 5.2 | 1 | ± 0.4 | ± 4.4 | |

Positoning speed | [mm/s; deg/s] | 700 | 0.5 | 0.5 | 0.4 | 0.4 |

| 30 | 40 | |

| Max. speed | [mm/s; deg/s] | 1400 | 1 | 1 | 0.8 | 0.8 | 60 | 80 | ||

Max. load | [N] |

|

|

|

| 20 |

| 40 | 150 | |

Motor |

| Iron Core Dynamic Linear Motor

|

| manually | DC Motor

| Stepper Motor | ||||

Guide |

|

| Solid State

| Solid State

| Solid State

| Solid State

| Sliding Guide |

| Profile Rail | |

Drive |

|

| Gear Box, Lead Screw | Gear Box, Lead Screw | Gear Box, Lead Screw | Gear Box, Lead Screw |

|

| ||

Feedback |

| Angular Scale | Scale | |||||||

| Aperture | [mm] | Ø 45 mm | ||||||||

| Length x width x height | [mm] | 600 x 600 x 880 | ||||||||

Integrated Controller

We support the integration of the motion controller directly into the positioning system.

FMC250/280

Multi-axis controller with increased current and voltage for point-to-point positioning.

FMC300

Installation module for dynamic applications and high loads and voltage.

FMC400/450

Multi-axis controller fully ready for tracking, simple creation of own programs.

ACS

We support integration of our systems into your ACS environment

PLC

We support integration of our systems into PLC architectures, e.g. Beckhoff

Used Standard Components

PLT165-SM

PMT160-DC

PMT160-SM

KGT 1214

Almost all atmospheric multi-axis combinations are unanodized with UHV lubrication for residual pressures up to 10-6 mbar and min. cleanroom class ISO 6 - or even better - available. Further stages for more demanding environments up to cleanroom class ISO 2, vacuum up to 10E-11 mbar or hard radiation you will find here:

Overview Clean Room & Vacuum Stages Get in touch with our technical consultant

Steinmeyer Mechatronik GmbH mainly uses aluminum for the structure of custom axis combinations, because it efficiently dissipates local heat and quickly reaches a thermally stable state. This is a prerequisite for stable, precise systems. The lower stiffness of aluminum compared to steel is compensated by a slightly higher height of the stages or the use of hollow profiles. Note: An aluminum beam and a steel beam sag equally under their own weight!

In special cases, titanium is also used for magnet-free systems.

What surfaces are available?

Various surface options are available. Depending on the application, anodized and cleaned, alternative colors, aluminum cleaned and bare, bilatal or nickel are available for optimal process suitability (e.g. particularly high degrees of purity, resistance to cleaning with chemicals in the field of life science). Special surfaces are often necessary for UV, DUV or EUV (X-ray, gamma on request).

Depending on the requirements, various drive systems can be used. This can be recognized as an abbreviation in the name below:

- Ground ball screws or lead screws with SM (stepper motor), DC motor or AC servo.

- Electrodynamic linear motors (ironless or iron-core).

- Piezomotors such as Piezo-Legs® or Nanomotion®.

Incremental scales made of steel or Zerodur® or Zeromet® are used as a feedback system in most cases. While this is sufficient for accuracy in the single-digit micrometer range, it makes sense to use interferometric position feedback for accuracy requirements below one micrometer. In systems with “open loop”, i.e. without a measuring system, only precision in the double-digit micrometer range can be achieved; however, due to the simpler controller and the lack of a measuring system, this is the more cost-effective solution.

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references