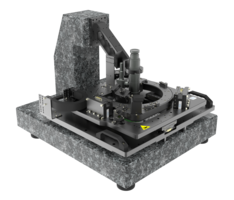

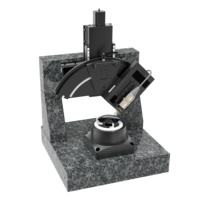

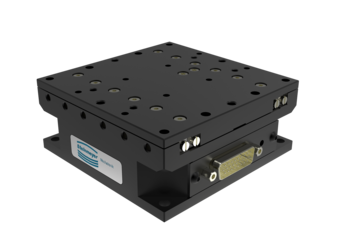

6-axis miniature XYZ-Theta-Phi-Delta positioning system (clean room ISO 5) | Tripod, Rotary Stage, XY- Stage, Hexapod Alternative | Travel XYZ 30 x 30 x 20 mm, RxRy 4°, Rz 360°

XYZ Tip-Tilt System

786015:009.26

6-axis alignment of wafers and optics up to 12"

The 6-axis manipulator includes an XY Stage in the horizontal axis and a Tripod for vertical strokes and two tilts, which combines the strengths of cartesian and parallel kinematic designs in one system. The cartesian XY adjustment realizes travel ranges of ± 15 mm, the vertical axis of the tripod is designed for strokes of ±10 mm. The rotatory axes Rx and Ry allow tilts of ± 2°, the rotational motion around the vertical Rz is 360°.

Automated clean room inspection

|

|

|

|

Options:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired motion control or the completely individual solution development with 3D design for the application-specific positioning task.

Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Semiconductor inspection, alignment, wafer, optics, manipulator, parallel kinematics, testing and bonding on wafers and PCB, combinations of optical inspection and processing e.g. for chip-on-board bonding (measuring microscope and laser soldering)

| 786015:009.26 | X | Y | Z | Rx | Ry | Rz | |

| Standard System | MT95 | MT95 | 3x MT95 | 3x MT95 | 3x MT95 | ||

| Travel | [mm; deg] | 30 | 30 | 20 | 4 | 4 | 360 x n |

| Repeatability unidirectional | [µm; deg] | ± 1.5 | ± 1.5 | ± 1.5 | 0.0004 | 0.0004 | 0.05 |

| Repeatability bidirectional | [µm; deg] | ± 3.5 | ± 3.5 | ± 3.5 | 0.001 | 0.001 | 0.1 |

| Positioning speed | [mm/s; deg/s] | 1.1 | 1.1 | 1.1 | 0.3 | 0.3 | 100 |

| Max. speed | [mm/s; deg/s] | 2 | 2 | 2 | 0.5 | 0.5 | 200 |

| Max. load | [N] | 65 | 65 | 100 | 65 | 65 | 20 |

| Motor | DC-Motor | DC-Motor | DC-Motor | DC-Motor | DC-Motor | Stepper Motor | |

| Drive | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Ball screw 1112, Gear Box, Belt | Belt | |

| Feedback | Motor-Encoder | Motor-Encoder | Motor-Encoder | Motor-Encoder | Motor-Encoder | - | |

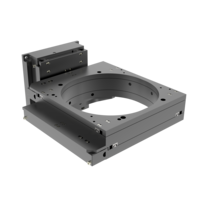

| Aperture diameter | [mm] | 250 (optional larger as special version) | |||||

| Max. sample diameter | [mm] [inch] | 300 12 (450 mm / 18" optional as special version) | |||||

| Length x width x height | [mm] | 520 x 600 x 155 | |||||

Used Standard Components

MT95-DC

KGT 1112

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references