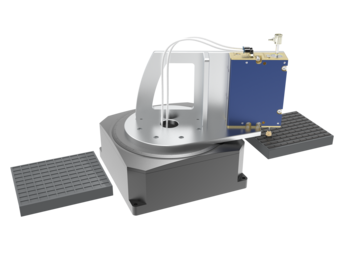

Linear Rotary Actuator (Z-Phi) with integrated motion control for automated precision assembly

Handling and Production

786008:002.26.Rz

High-precision automated assembly of miniaturized components

This industrial rotary-stroke actuator with integrated pneumatic control allows sensitive as well as very fast combined rotary and linear motion. It is particularly suitable for automated and low-maintenance pick-and-place assembly systems. The rotary stroke enables the removal of the component to be positioned from the automatic magazine feed, detection in position and, if necessary, correction and positioning with controlled contact pressure.

The internal control with field bus interface is plug-and-play ready and is located directly in the positioning unit. In addition, this allows internal storage of error information for automatic compensation. Also integrated is a concept for remote maintenance and remote diagnostics.

Integrated error compensation, remote maintenance and service

|

|

|

|

|

|

Special features:

|

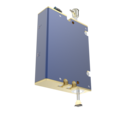

Integrated controller in the smallest possible space

The entire embedded control electronics in a scope of two 19-inch racks is housed on a single printed circuit board. The device status can be reported back to the control computer by streaming or polling.The error information is stored internally and is taken into account by the motion controller during control. In the event of servicing, the plug-and-play feature offers fast, uncomplicated replacement.The integration of the controller into the positioning unit also enables certain parameters to be monitored - such as maximum speed during initialization (self-diagnosis) or tracking errors during operation, so that machine downtimes can be avoided by intervening in good time. Other helpful functions include an operating hours counter and a non-volatile error memory. Through the connection via EtherCAT or CAN, updates can be made with improvements in programming or parameterization can be implemented worldwide without any problems.

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Automated assembly systems for printed circuit board assembly with joining modules, assembly of electronic components / sensors, alignment of optical components, cameras, autonomous driving systems, sensors, cell phones, electronic devices, cardiac pacemakers, insulin pumps

786008:002.26.Rz |

| Z Linear Stroke | Rz Linear Stroke | Rz Rotary Stage |

| Standard System | 786008:002.26 | 786008:002.26 | DT240 | |

[mm; deg] | 14 | n x 360 | n x 360 | |

[µm; deg] | ± 7 | ± 0.03° | ± 0.0001 | |

| Repeatability bidirectional | [µm; deg] | ± 10 | ± 0.05° | ± 0.0002 |

[mm/s; deg/s] | 500 | 2769 | 1500 | |

| Max. Speed | [mm/s; deg/s] | 1000 | 5538 | 3000 |

Max. Load | [N] | 0.5 | 0.5 | 400 |

Motor |

| Iron Core Dynamic Linear Motor

| Stepper Motor | Torque Motor |

Drive |

|

| Belt | |

Feedback |

| Inductive Sensor | Inductive Sensor | Angular Scale |

Used Standard Components

DT240-TM

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references