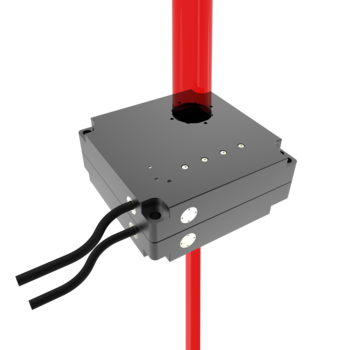

XY aperture adjuster | variable, square high-precision laser beam shaping for laser micromachining | motorized

Precision Assemblies and Components

786006:001.26

Variable square laser beam shaping for power lasers

The aperture control is used to set a pass window for a power laser. This window makes it possible to mask the laser beam. For this purpose, individual apertures are positioned to create all square imaging shapes. The beam center is fixed and not changeable.

|

|

|

|

Optionally expandable:

|

Highest precision and compact design

The pairs of individual apertures must be moved synchronously to adjust the aperture window. Two individual apertures are adjusted by each spindle. The aperture controller is driven by a DC motor and a precision spindle. The motor can generate two counter-rotating movements. In addition, the flat design requires only a small installation length in the optical path. The pairs of individual apertures must be moved synchronously to adjust the transmission window, two individual apertures are adjusted by one spindle each. The parallelism of the opposite diaphragms is only 10 µm maximum.

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Applications

Realization of complex geometries in laser micro processing e.g. micro laser sintering, laser fine cutting, laser micro structuring, micro structure diagnostics, laser micro drilling, laser micro engraving, additive manufacturing

| 786006:001.26 | X | Y | |

| Travel | [mm; deg] | 25 | 25 |

| Repeatability unidirectional | [µm; deg] | ± 2 | ± 2 |

| Repeatability bidirectional | [µm; deg] | ± 2.7 | ± 2.7 |

| Positioning speed | [mm/s; deg/s] | 0.5 | 0.5 |

| Motor |

|

| |

| Drive | |||

| Feedback | Motor-Encoder | Motor-Encoder |