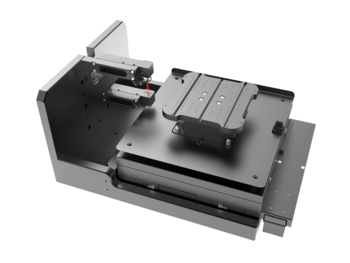

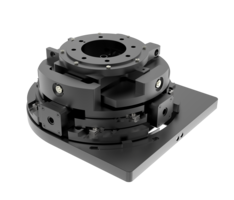

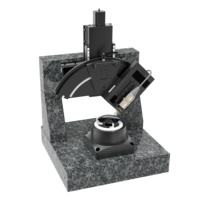

XY-Rz positioning system (cleanroom ISO 6) | XY linear motor, linear scale | Theta AC servo, harmonic drive | Travel 170 × 170 mm × 360°

XY Theta Stage

782460:001.26

Precise XY-Rz Positioning

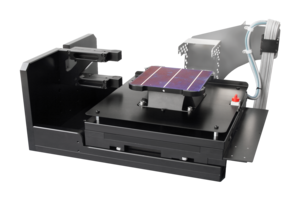

The positioning system moves the sample using an XY platform with a KT305-EDLM linear stage and an integrated rotary unit (theta axis). The sample is fixed via a vacuum chuck and precisely aligned at the edges using a light barrier system. Processing and measurement are then carried out.

|

|

|

|

Options:

|

Application Fields

Inspection, structuring, microscopy, metrology, quality assurance, precision machining, semiconductor technology, automation

| 782460:001.26 | X | Y | Rz | |

| Standard system | KT305-edlm | KT305-edlm | DE130-AC | |

| Travel | [mm; deg] | 170 | 170 | n*360 |

| Repeatability unidirectional | [µm; deg] | ± 0.4 | ± 0.4 | 0.005 |

| Repeatability bidirectional | [µm; deg] | ± 0.5 | ± 0.5 | 0.007 |

| Positioning speed | [mm/s; deg/s] | 50 | 50 | 180 |

| Max. speed | [mm/s; deg/s] | 100 | 100 | 360 |

| Max. load | [N] | 50 | 50 | |

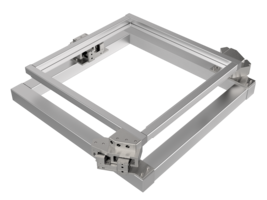

| Dimensions (L × W × H) | [mm] | 515 × 350 × 220 | ||

| Max. sample size | [mm] | 156 × 156 mm / 6" | ||

| Weight | [kg] | 44 | ||

| Motor | Dynamic Linear Motor (Ironless) | Dynamic Linear Motor (Ironless) | AC Servo (AC) | |

| Drive | Harmonic Drive | |||

| Feedback | Linear Scale | Linear Scale | Motor Encoder | |

| Resolution of measuring system | optional up to 0.1 µm, 0.001 µm or better | |||

| Optional features | Alternative linear and rotary stages available, configuration for laboratory and cleanroom applications (up to ISO class 6 or better), integration of additional sensors or camera systems, customizable software for user-specific positioning algorithms, optional protective covers and vacuum components, base plate (granite / aluminum), frame, enclosure, customized vibration isolation using damping rubber layers or pneumatic dampers, safety concept and technology (emergency stop, door switches, light curtains, laser scanners, STO, SLS) | |||

| Cleanroom versions | up to cleanroom class ISO 6 (higher on request) | |||

| Beam variants | UV (DUV, EUV, X-ray, gamma on request) | |||

| Magnetism variants | magnetic | |||

Used Standard Components

KT305-EDLM

Related Products

The architecture of a multi-axis system has a significant influence on installation space, dynamics, accuracy, controller requirements, and cost. The rating scale is: +++ low / ++ medium / + high.

| Criterion | Stacked (XY-Z) | Portal (X-YZ) | Gantry (2X-YZ / 2XY-Z) |

|---|---|---|---|

| Installation space (footprint, structural cost) | + | +++ | ++ |

| Natural frequency (stiffness, settling time, sensitivity to external disturbances) | + | ++ | +++ |

| Dynamics (speed, acceleration, cycle time) | + | ++ | +++ |

| Accuracy | + | ++ | +++ |

| Controller requirements (gantry mode, cost) | +++ | +++ | ++ |

| Total cost | +++ | +++ | ++ |

- Stacked: Ideal for compact, cost-efficient systems with high dynamics; limited for very large working areas.

- Portal: A balanced compromise between stiffness, dynamics, and working area; higher mechanical and control effort.

- Gantry: Optimal for large working areas and high planarity requirements; highest complexity, controller requirements, and cost.

In addition to these basic architectures, Steinmeyer Mechatronik also offers compact multi-axis combinations as well as custom-specific solutions—depending on installation space, load, dynamics, and accuracy requirements.

The specifications are based on a right-handed, system-oriented coordinate system. The designation of the axes and degrees of freedom follows the assignment below:

| Degree of freedom | Designation at STM | Description |

|---|---|---|

| Translation X | X | Direction of travel away from the motor or head end |

| Translation Y | Y | Lateral direction of travel |

| Translation Z | Z | Vertical movement opposite to gravity (↑) |

| Rotation about X (Rx) | ω (Omega) | Roll |

| Rotation about Y (Ry) | φ (Phi) | Pitch |

| Rotation about Z (Rz) | θ (Theta) | Yaw |

Is there a standardized coordinate system for axis designation in positioning applications?

Unfortunately not. Especially for rotational degrees of freedom, there is no globally standardized designation, and naming conventions depend strongly on the specific discipline (e.g., mechanics, robotics, aerospace, mechanical engineering, CNC technology, optics).

Below is an overview of how rotational axes (rotational degrees of freedom) are commonly designated, grouped by application area.

1. General mechanical definition (DIN / ISO / robotics / mechatronics)

- Translational axes: X, Y, Z

- Rotational axes:

- Rx – Rotation about the X-axis (→ roll motion)

- Ry – Rotation about the Y-axis (→ pitch motion)

- Rz – Rotation about the Z-axis (→ yaw motion)

This notation is clear, unambiguous, and widely used in mechatronics, robotics, and kinematic analysis.

It is used, for example, in Denavit–Hartenberg parameters, CAD systems (SolidWorks, Creo, Siemens NX), and robot programming languages (KUKA, FANUC, UR).

2. Aerospace / navigation systems (Euler angles)

- Roll (φ) – Rotation about the X-axis

- Pitch (θ) – Rotation about the Y-axis

- Yaw (ψ) – Rotation about the Z-axis

These designations are firmly established when it comes to spatial orientation (e.g., for drones, aircraft, gimbals, cameras).

To add to the confusion, this even involves a left-handed coordinate system. Pilots are well aware that gravity points toward the center of the Earth and therefore define the Z-axis as positive downward.

Mechanical engineers do not find this positive. In their convention, Z points upward.

3. CNC technology / machine tools (DIN 66217, ISO 841)

Here is the conventional machine axis designation:

| Axis | Motion | Description | Example |

| X, Y, Z | Translation | Linear axes | Workpiece movement or tool feed |

| A | Rotation about X | e.g., tilting table, rotary axis | |

| B | Rotation about Y | e.g., swivel head | |

| C | Rotation about Z | e.g., rotary table |

This is the common nomenclature for machining centers, rotary tables, hexapods, etc.

4. Optics / metrology / precision mechatronics

In highly precise positioning systems, the mathematically rigorous notation from kinematics is often preferred:

- Translations: X, Y, Z

- Rotations: θx, θy, θz

or alternatively φx, φy, φz

This notation is advantageous when rotations are specified in the microradian or µrad range (e.g., for wobble, tilt, angular errors).

Yes. Many multi-axis systems are modular in design and can be adapted to changing requirements. From the initial design stage, provisions are made to allow for extensions, reconfiguration, or functional adaptations.

- Integration of additional process heads

- e.g., measurement, inspection, machining, or handling modules

- Replacement or addition of axes and crossbeams

- Expansion of the working area

- Adaptation to new motion profiles

- Adaptation of the system architecture

- Conversion from stacked to portal or gantry structures (application-dependent)

- Mechanical modifications

- Adjustment of travel ranges, load interfaces, or mechanical interfaces

- Optional functional and equipment upgrades

- Encoders, measurement systems, brakes

- Customer-specific surfaces and coatings

- Adaptation to new process or environmental requirements

- Cleanroom or vacuum environments

- Life science, optics, or semiconductor applications

The degree of modularity depends on the specific system architecture, accuracy requirements, and application. In many cases, a subsequent expansion is more economical than a complete redesign.

- Optimized system architecture: selection of suitable architecture types (e.g., stacked, portal, gantry) matched to the application

- Targeted material selection: use of structurally stable materials to minimize vibration effects

- Well-engineered design principles: stiff structures, short force paths, and a symmetrical layout

- High natural frequency: facilitates system tuning and reduces sensitivity to external disturbances

- Result:

- improved dynamics

- higher positioning accuracy

- stable operation even at high accelerations

Almost all atmospheric multi-axis combinations are unanodized with UHV lubrication for residual pressures up to 10-6 mbar and min. cleanroom class ISO 6 - up to ISO class 2 -1 on request - available. Further stages for more demanding environments up to cleanroom class ISO 2, vacuum up to 10E-11 mbar or hard radiation you will find here:

Overview Clean Room & Vacuum Stages Get in touch with our technical consultant

Materials

Steinmeyer Mechatronik GmbH predominantly uses aluminum for the structure of multi-axis positioning systems.

In special cases, steel and titanium (e.g., for non-magnetic systems) are also possible.

The reason: aluminum efficiently dissipates localized heat, allowing the system to quickly reach a thermally stabilized state—an essential prerequisite for stable and highly accurate positioning systems.

The lower stiffness of aluminum compared to steel is compensated for by design measures, such as:

- a slightly increased table height

- the use of hollow profiles

Important: An aluminum beam and a steel beam with identical geometry exhibit the same deflection under their own weight. For special requirements—e.g., non-magnetic applications—titanium versions are also available.

Functional surfaces and coatings

In addition to standard surfaces, numerous customer-specific surface and coating concepts are available.

These are specifically designed to achieve very high cleanroom classes—up to ISO 1–2, depending on the application and process.

To meet demanding process requirements, we develop and qualify application-specific functional coatings, including:

- Nickel coatings

- PTFE & KEPLA® coatings

- Fluorinated lubricants

- Dicronite® / dry-film coatings

- Application-specific coating combinations

In addition, the following options are available:

- anodized (cleaned)

- alternative color anodizing

- bare aluminum, cleaned

- Bilatal

- Nickel

These surfaces are suitable, for example, for high purity requirements, chemical resistance (life science), or process-critical environments.

Why functional coatings are crucial (before → after)

- Standard surface → EUV-compatible surface

- Reflective → non-reflective, minimized stray light

- Limited sliding capability → maximum sliding performance & reduced wear

- Basic protection → chemical & corrosive resistance

- One-size-fits-all → cost-optimized, application-specific performance

Special surfaces are often required for UV / DUV / EUV applications (X-ray or gamma applications on request).

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references