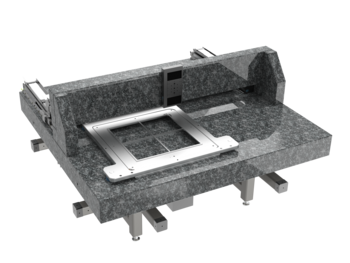

XY-2Z 4-Axis Gantry with aperture | XY linear motor, profile rail, air bearing | Z ball screw, DC motor | Travel 600 x 600 x 100 x 100 mm

Gantries

782300:183.26

Gantry with aperture and bilateral sensor positioners

This XYZ gantry positioning system allows high precision bilateral inspection processes with 2 custom sensors / microscopes each for different metrology applications. The first Z-axis is located on the stationary traverse, the second sensor / microscope is mounted on the Z-axis below the aperture. The air-bearing sample holder moves the sample in XY direction to the aperture with the two sensors on the Z-axes, each of which can be adjusted in height of 100 mm.

For automatic bilateral inspection processes

|

|

|

|

|

Optionally configurable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Differential height measurement on contours of chips in PCB panels, automatic optical inspection e.g. printed circuit boards, wafer structures, microelectronics, microlenses, thin film solar cells, test systems, creation of 3D surface profiles, profile measurement, layer thickness measurement, observation of surface changes, roughness, curvature of surfaces, 3D white light interferometry, inspection of medical implants

782300:183.26 |

| X | Y | Z1 | Z2 |

| Standard System | PLT165-DLM | PLT165-DLM | PMT160-DC | PMT160-DC | |

[mm; deg] | 600 | 600 | 100 | 100 | |

Repeatability unidirectional | [µm; deg] | ± 1.4 | ± 0.7 | ± 0.2 | ± 0.2 |

Repeatability bidirectional | [µm; deg] | ± 2 | ± 1 | ± 0.7 | ± 0.7 |

[mm/s; deg/s] | 500 | 500 | 10 | 10 | |

| Max. speed | [mm/s; deg/s] | 1000 | 1000 | 20 | 20 |

| Max. load | [N] | 150 | 150 | ||

Motor |

| ||||

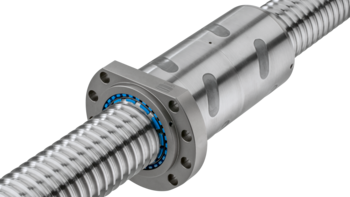

Drive |

|

| |||

| Guide | Profile Rail | Profile Rail | Cross Roller | Cross Roller | |

Feedback |

| Linear Scale | |||

| Aperture | [mm] | 70 x 100 | |||

| Lange x Breite x Höhe | [mm] | 1850 x 1920 x 1150 | |||

Used Standard Components

PLT165-DLM

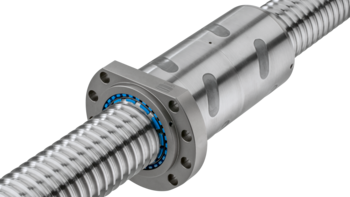

PMT160-DC

KGT ETA+

KGT ETA+