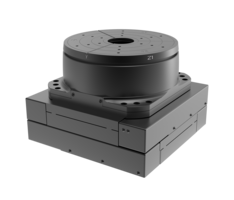

MP200-3 Miniature Z-Phi Delta Positioning System, Tripod | Stepper Motor, Lead Screw | Travel 2 mm x 1.5° x 1.5°

XYZ Tip-Tilt System

Art. ID 225692 / 782497:008.26 (-5)

Tripod with aperture

As a addition to the MP200-5 aligner, which allows adjustment in five degrees of freedom, this aligner was designed with three degrees of freedom. It consists internally of three vertically acting precision axes, which are connected to the movable load plate by means of solid joints. Thus, the load plate can be tilted in two axes and also adjusted in height.

|

|

|

Options:

|

Use in wafer inspection and for high-precision assembly tasks

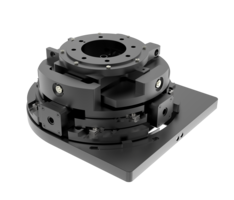

Since alignment of workpieces is often sufficient, vertical adjustment can be used to compensate for lens packages of different heights, especially in optics assembly. In addition, a 5-axis manipulator with a large travel range in XY can be realized from this manipulator and a cross-transmitted light table or cross table. For example, the KDT310, KT310 or KDT235 can be used as XY systems.

| MP200-3 | Z | Rx | Ry | |

| Standard System | MT63-DC | MT63-DC | MT63-DC | |

| Travel | [mm] | 4 | 3 | 3 |

| Repeatability unidirectional | [µm] | ± 0.5 | ± 0.00005 | ± 0.00005 |

| Repeatability bidirectional | [µm] | ± 2.5 | ± 0.00020 | ± 0.00020 |

| Positioning speed | [mm/s] | 1 | 0.8 | 0.8 |

| Max. speed | [mm/s] | 1.8 | 1.5 | 1.5 |

| Max. Load | [N] | 20 | ||

| Length x width x height | [mm] | 200 x 200 x 80 | ||

| Aperture | [mm] | Ø 45 | ||

| Weight | [kg] | 6.5 | ||

| Drive | Lead Screw, Belt | Lead Screw, Belt | Lead Screw, Belt | |

| Screw type | M5x0,5 | M5x0,5 | M5x0,5 | |

| Lead | 0.5 | 0.5 | 0.5 | |

| Motor | DC-Motor | DC-Motor | DC-Motor | |

| Feedback | Motor Encoder | Motor Encoder | Motor Encoder | |

| Resolution Measuring System | 0.1 µm (optional up to 0.001 µm) | |||

| Material | Anodized Aluminum | |||

| Optional features | Rotary stage, sample holder, calibreless energy supply for unlimited rotation | |||

| Variants clean room | up to cleanroom class ISO 4 (higher on request) | |||

| Variants beam | UV, DUV (EUV, X-ray, gamma on request) | |||

| Variants magnetism | magnetic (low-magnetic on request) | |||

| Variants vacuum | up to 10E-6 mbar (higher on request) | |||

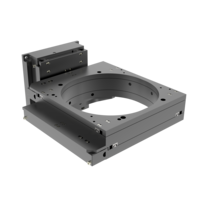

Used Standard Components

MT63-DC

Related Products

Are you looking for a technical solution for your application?

Get your first 3D Design in a few days:

Katja Weißbach

Consulting

T +49 351 88585-64

E-Mail

Ronald Schulze

Consulting, Project Management & Engineering

T +49 351 88585-67

E-Mail

Francisco Samuel

Consulting &

Project Management

T +49 351 88585-85

E-Mail

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail

Our references