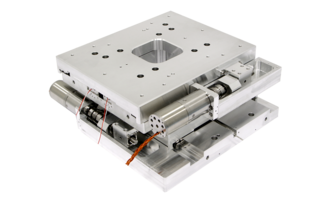

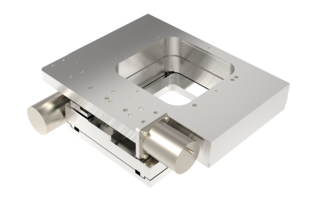

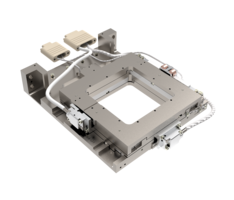

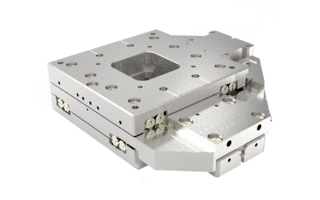

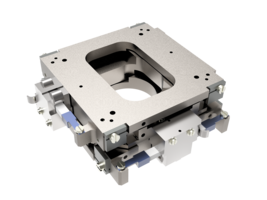

KLT310

Vacuum / Cleanroom XY stages

782330:178.26

Heavy-Duty XY Stage

HV, DUV, cleanroom ISO 6, travel 100 x 100 mm, repeatability up to 0.7 µm, speed 20 mm/s, load capacity up to 28 kg

|

|

|

|

|

Optionally configurable:

|

Ideal for demanding inspection tasks

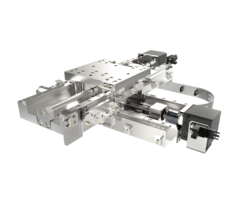

The cross table combines two high-precision screw-driven axes, achieving excellent accuracy values. With its robust design and a travel range of 100 mm in both X and Y directions, the KLT310 enables precise positioning even for heavy loads. With its performance characteristics, the KLT310 is ideal for high-precision inspection processes.

It can be easily combined with the DT155 rotary table, allowing for a wide range of applications.

Application Areas

Precision positioning for laboratory applications, microscopy and semiconductor technology, research in ultra-high vacuum and under extreme ultraviolet radiation, sample preparation, sample scanning, sample handling, biochips, wafer inspection, wafer alignment, camera alignment, materials research, materials analysis, beamlines, accelerators, synchrotron

| KLT310 | -100-SM | -100-SM-L | |

| Standard System | LT310 | LT310 | |

| Travel | [mm] | 100 x 100 | 100 x 100 |

| Repeatability unidirectional | [μm] | ± 1.6 | ± 0.7 |

| Repeatability bidirectional | [μm] | ± 2.1 | ± 0.5 |

| Positioning speed | [mm/s] | 10 | 10 |

| Max. speed | [mm/s] | 20 | 20 |

| Max. load Fx | [N] | 45 | 45 |

| Max. load Fy | [N] | 45 | 45 |

| Max. load Fz | [N] | 280 | 280 |

| Length | [mm] | 310 | 310 |

| Width | [mm] | 310 | 310 |

| Height | [mm] | 100 | 100 |

| Aperture Y | [mm] | 150 x 150 | |

| Weight | [kg] | 15 | |

| Lubrication liquid | [mbar] | up to 10-7 | |

| Max. Bakeout temperature | [deg] | 100 | |

| Drive | Ball Screw 1214.545/1.8.138.188R P3P | ||

| Screw lead | 1 | ||

| Bearing | profile rail | ||

| Motor | Stepper Motor | ||

| Feedback | Open Loop | Linear Scale | |

| Resolution measuring system | without | 0.05 µm, optional up to 0.001 µm | |

| Optional features | Lead screw with dry lube or ball screw with liquid lube, different motor types, custom fluorine-free / PFAS-free UHV lubrication, adapter, bore grid, cable / plugs | ||

| Variants clean room | up to cleanroom class ISO 6 (higher on request) | ||

| Variants beam | UV, DUV (EUV, X-ray, gamma on request) | ||

| Variants magnetism | magnetic | ||

| Variants vacuum | all ranges up to 10E-7 mbar HV | ||

Used Standard Components

KGT 1214

Related Products

201/5000 Even more axes for your vacuum applications

Almost all atmospheric standard axes are anodized with UHV lubrication for residual pressures up to 10-6 mbar - or even better - available. Click here for the overview of our standard axes!

Overwiew standard stages Contact technical consultants

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail