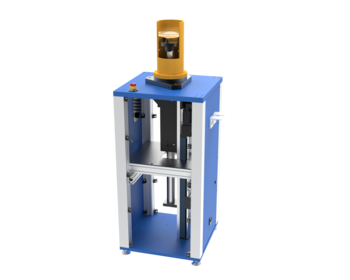

Stacking unit Z | Mounting of long optics in defense applications

Precision Assemblies and Components

782478:001.26 / 782478:002.26

Precise alignment of cylindrical lens systems

The Stacking Unit Z was developed for the accurate vertical assembly of lenses into long-bodied optical systems. The goal is to insert optical components, whose lateral position has been previously measured, into cylindrical housings without any deviation. Even minimal pitch or yaw errors during guidance would cause the lateral position of the lens to deviate from its intended alignment, ultimately affecting the imaging performance.

|

|

|

|

Optional:

|

Process-reliable solution

Whether for underwater reconnaissance, precision targeting optics, or airborne sensor systems – wherever long optics require exact alignment, the Stacking Unit Z offers a process-reliable solution. Manufacturers of military optics – such as for periscopes, targeting systems or UAV sensors – benefit from the frictionless air bearing guide and mechanically decoupled drive system. This eliminates any influence from torsional or axial forces, ensuring maximum process reliability even when handling sensitive lenses or complex assemblies.

The system is designed for long strokes up to 550 mm, with a high repeatability of ± 2.3 µm. Even heavy optical components up to 250 N can be safely and accurately mounted. Lateral deviation over the entire stroke remains below 10 µm. Cleanroom-compatible versions up to ISO Class 6 are available for sensitive production environments.

Fields of application

Assembly of periscopes and photonic masts in submarines, Alignment of targeting optics, collimators or autocollimation telescopes, Integration of optical systems into UAVs, reconnaissance units, and laser targeting systems

| 782478:001.26 / 782478:002.26 | Z | |

| Standard-Stage | LTP80 | |

| Travel | [mm] | 245 / 550 |

| Repeatability unidirectional | [µm] | ± 2.3 |

| Repeatability bidirectional | [µm] | ± 4.3 |

| Positioning speed | [mm/s] | 10 |

| Max. speed | [mm/s] | 30 |

| Max. acceleration | [m/s2] | 30 |

| Max. load Fx | [N] | 250 |

| Motor | AC | |

| Drive | Ball Screw Drive 1432.506/5.12.651.697 T7P / 150505 | |

| Bearing | Air Bearing | |

| Feedback | Motor Encoder | |

| Material | Anodized Aluminum, System Housing | |

| Optional features | Housing, break, custom adapter, custom controls and software | |

| Variants cleanroom | up to clean room class ISO 6 (higher on request) | |

| Variants beam | UV (DUV, EUV, X-ray, gamma on request) | |

| Variants Magnetism | magnetisch | |

| Variants vacuum | - |

Elger Matthes

Consulting, Concepts, Innovation & Engineering

T +49 351 88585-82

E-Mail