Herausgeber: Medical Design 2021-04-29 | www.medical-design.news

Original Publikation öffnen open System

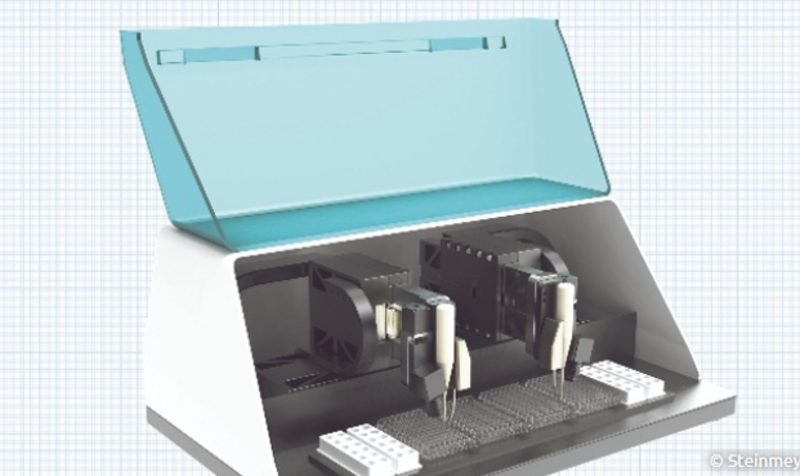

Fast and precise analysis of microplates

Whether healthcare, life science or pharmaceutical: when it comes to processing and analyzing a large number of samples, microplates are the tool of choice. Precision and speed are the be-all and end-all. With the new microtiter scanning system, the manufacturer says it offers the right solution for this. The XY-Z platform was developed specifically for fast scanning tasks in medical technology and takes the screening of microtiter plates to a new level.

The new microtiter scanning system from Steinmeyer Mechatronik ensures high-precision positioning with a repeatability up to 5 µm, enabling consistent results with a minimized error rate. The high-resolution 25-mm focus axis with µm resolution is said to ensure optimum analysis results. It can be equipped with a double or single sensor arm.

The linear motor used offers high speeds as well as accelerations, which guarantees fast and controlled scanning of the samples at up to 500 mm/s. Up to 120 well plates can be scanned per hour with single pipette or single sensor. Operation can be either in on-the-fly mode with position trigger or in inertia-compensated start-stop mode with two actuators.

Easy handling in the clean room

In addition, the high level of user-friendliness makes work easier. For example, the XY-Z system is low in contamination and, thanks to air bearings, is maintenance-free even in 24/7 operation. The bus connection ensures simple integration into the system control. It goes without saying that the system is suitable for use in cleanrooms; versions up to Class 6 in accordance with ISO 14644-1 can be implemented. The system is scalable and can be expanded to 8 or 16 plates.