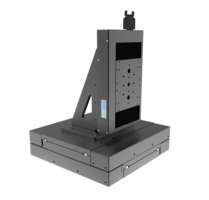

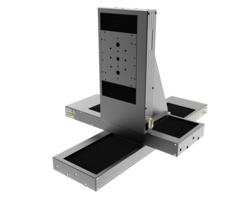

XYZ system for inspection and quality control | XY DC motor, cross roller| Z DC motor, ball screw, linear measuring system

Combinations of laboratory axes

782300:193.26

High-precision inspection with minimum error rate

The positioning system enables positioning along three linear axes. In this unit, a PMT160 linear stage is mounted on a KT470 cross table with an adapter bracket. It achieves low runout errors, in terms of straightness and flatness, which are achieved by using crossed rollers. This results in above-average repeatability, which is the basis for good compensation. This enables extremely high accuracy for measurement applications.

Ideal for optical quality control

|

|

|

|

|

Optional expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Fast scanning applications in start-stop mode e.g. single measurements, automatic optical inspection (AOI), 3D imaging, microscopy, imaging systems, laboratory applications, quality assurance, 3-axis sensor measurement, wafer inspection

782300:193.26 | X | Y | Z | |

Travel | [mm; deg] | 300 | 300 | 100 |

Repeatability unidirectional | [µm; deg] | ± 1.7 | ± 1.7 | ± 1.7 |

Repeatability bidirectional | [µm; deg] | ± 0.3 | ± 0.3 | ± 0.3 |

|

Positioning speed | [mm/s; deg/s] | 25 | 25 | 25 |

Max. load | [N] | 45 | 150 | 150 |

Motor |

| DC-Motor | DC-Motor | DC-Motor |

Feedback | Linear Scale | Linear Scale | Linear Scale |

Verwendete Standard Komponenten

KT470-DC

PMT160-DC

KGT 1214

Verwandte Produkte

Sie suchen eine technische Lösung für Ihre Anwendung?

Jetzt den ersten 3D Entwurf in nur wenigen Tagen erhalten:

Elger Matthes

Beratung, Konzepte, Innovation & Engineering

T +49 351 88585-82

E-Mail