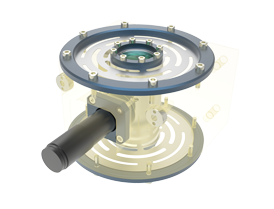

One of the latest OEM developments from Steinmeyer Mechatronik is the DT232 - a rotary stage for monitoring tasks. Exemplifying many other OEM developments, the company designed a system to use a radar sensor to implement a monitoring device.

In close dialogue with the user, a cost-optimized solution with the rotary stage DT232 was created which would not have been possible simply by combining commercially available components.

For the task, a continuously running, flat rotary stage with large aperture was necessary. A direct drive was used to ensure long-term continuous operation. Motors with this design were not available. For cost reasons thin section bearings and angle measuring systems were not used. Instead, the motor and the angle measuring system have been integrated into a customized PCB assembly to realize the desired functionality in the given cost range.

Steinmeyer Mechatroniks plans to expand its capacities for OEM development and production in 2018 with further projects.