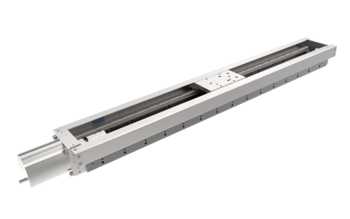

LA80

Vacuum / Cleanroom compact multi axes systems & aligner

782475:038.26, 782475:049.26

High speed linear stage

HV / UHV / EUV, ISO 4, 200 -500 mm travel, 0.4 µm repeatability, 5 kg load

|

|

|

|

|

|

Optionally configurable:

|

Long lifetime despite dry running

This linear axis is used as a powerful component for multi-axis systems and for highly dynamic transfer systems. It enables fast positioning with extremely high resolution in ultra-high vacuum, even in the vertical direction. A ball screw ensures high stiffness and standstill stability at high speed. The system does not require liquid lubricants and still offers lifetime in the range of many kilometers.

Fields of application

High-precision transfer systems in ultra-high vacuum under extreme ultraviolet radiation, semiconductor fabrication, beam shaping for exposure processes, surface analysis and sensor positioning, mass spectrometry, OLED coating processes, layer thickness measurement and layer rate measurement, surface coating (sputtering, vapor deposition), beam exits, experimental setups, sensor arrays for investigations of samples close to their native state

References

OMNY—A tOMography Nano crYo stage | Review of Scientific Instruments 89, 043706 (2018) | https://doi.org/10.1063/1.5020247

| LA80 | -200-SM | -200-SM-L | -500-SM | -500-SM-L | |

| Travel | [mm] | 200 | 200 | 500 | 500 |

| Repeatability unidirectional | [μm] | ± 3 | ± 0.3 | ± 3 | ± 0.3 |

| Repeatability bidirectional | [μm] | ± 4 | ± 0.5 | ± 4 | ± 0.5 |

| Positioning speed | [mm/s] | 50 | 50 | 50 | 50 |

| Max. speed | [mm/s] | 100 | 100 | 100 | 100 |

| Max. load Fx | [N] | 49 | 49 | 49 | 49 |

| Max. load Fy | [N] | 49 | 49 | 49 | 49 |

| Max. load Fz | [N] | 9 | 9 | 9 | 9 |

| Length | [mm] | 446 | 446 | 706 | 706 |

| Width | [mm] | 86 | 86 | 86 | 86 |

| Height | [mm] | 61 | 61 | 51 | 51 |

| Lubrication liquid | [mbar] | up to 10-8 | |||

| Lubrication dry | [mbar] | up to 10-11 | |||

| Max. Bakeout temperature | [deg] | 120 | |||

| Motor | Stepper Motor | ||||

| Bearing | stainless steel hybrid, Recirculating Ball Guides | ||||

| Feedback | Open Loop | Linear Scale | Open Loop | Linear Scale | |

| Resolution Measuring system | 0.5 µm | 0.5 µm | |||

| Optional features | lead screw with dry lube or ball screw with liquid lube, custom fluorine-free / PFAS-free UHV lubrication, adapter, bore grid, cable / plugs | ||||

| Variants clean room | up to clean room class ISO 4 (higher on request) | ||||

| Variants beam | UV, DUV, EUV (X-ray, gamma on request) | ||||

| Variants Magnetism | magnetic | ||||

| Variants vacuum | all ranges up to 10E-11 mbar HV / UHV | ||||

Noch mehr Achsen für Ihre Vakuumanwendungen?

Nahezu alle atmosphärischen Standardachsen sind eloxiert mit UHV-Schmierung für Restdrücke bis 10-6 mbar - oder noch besser - verfügbar. Klicken Sie hier für die Übersicht über unsere Standardachsen!

Laden Sie unseren Produktkatalog herunter:

Sie suchen eine technische Lösung für Ihre Anwendung?

Jetzt den ersten 3D Entwurf in nur wenigen Tagen erhalten: