Laser drilling head for the production of micro bores and micro cuts up to 60 µm | different bore geometries

Handling and Production

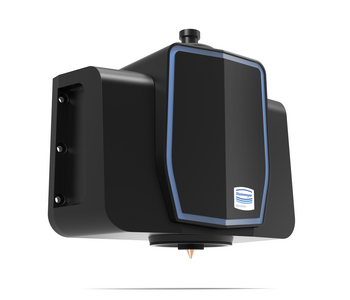

SLH200

Material processing with the highest precision

This industrial laser drill head is suitable for producing micro holes and micro cuts with precisely defined geometries. The laser drill head is based on rotating and tilting optics, which shape and focus the coupled beam. The focused beam is guided along a circular path on the workpiece. This well-known trepanning process enables highly precise and reproducible drilling geometries.

Long-term use in an industrial environment

|

|

|

|

|

Optionally expandable:

|

Different drilling geometries for a wide range of materials

The SLH200 laser drilling head was specially developed for industrial applications. The high-precision tilting of the optics relative to each other, influences the respective bore geometries. The integrated air bearings ensure an almost wear-free drive of all relevant rotating optical elements. As a result, this drill head achieves a unique service life combined with high reliability. The air-bearing optics are adjusted by two stepper motors to influence the parallel offset and the inclination angle.

Easy control

A simple and powerful set-up software matching the laser drill head is optionally available. The laser drill head is simply connected to the system control via USB or RS485, allowing the most important functions such as speed, parallel offset and tilt angle to be set quickly. All settings can be changed during operation within a few milliseconds. A freely programmable sequence makes it possible to write a short program that is then automatically processed step by step. With these functions, fast commissioning is possible. A comprehensive software interface can be offered for later integration into the user's own machine control system.

Application areas

Laser microdrilling for different bore geometries (straight, cylindrical, positive or negative open bore shape), laser microstructuring, manufacturing of precision mechanical components with exactly straight cutting edgesMillisekunden ändern. Eine frei programmierbare Sequenz ermöglicht es, ein kurzes Programm zu schreiben, dass dann automatisch Schritt für Schritt abgearbeitet wird. Mit diesen Funktionen ist eine schnelle Inbetriebnahme möglich. Für eine spätere Einbindung in die eigene Maschinensteuerung kann ein ein umfangreiches Software-Interface angeboten werden.

References

2013/03 Press Release Air Bearing Helical Drilling Optics

| SLH200 | Z | |

| Min. bore diameter | [µm] | <60 |

| Bore diameter resolution | [µm] | <1 |

| Bore inclination angle | [deg] | 4 |

| Bore inclination angle resolution | [deg] | <0.01 |

| Rotational speed | [rpm] | up to 6000 |

| Parallel offset | [µm] | 750 |

| Parallel offset resolution | [µm] | <1 |

| Adjustment speed parallel offset | [µm/s] | >3000 |

| Adjustment speed angle | [deg/s] | >10 |

| Collimated beam diameter | [mm] | 3...5 |

| Wellenlänge | [nm] | 515...532, 1030...1064 |

| Max. engery density at 10ns | [mJ/cm2] | 50 |

| Dimensions | [mm] | 270 x 260 x 135 |

| Weight | [kg] | 11 |

Verwendete Standard Komponenten

KGT 1112

Sie suchen eine technische Lösung für Ihre Anwendung?

Jetzt den ersten 3D Entwurf in nur wenigen Tagen erhalten:

Unsere Referenzen