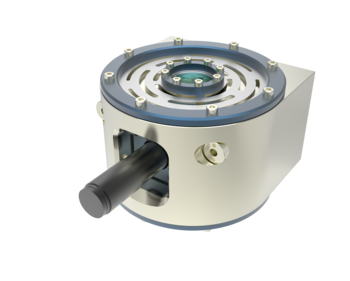

Z Focus axis for confocal optics, LSCM | automated and high-resolution analysis and microscopy applications

Laboratory / Analytics

ID 219595

High-resolution, industrial-grade and cost-optimized

This positioning system for automated confocal microscopy and camera applications enables more than 100 million focalizations and produces excellent images. Especially for confocal optics, smallest positioning steps below one micrometer and minimal deviations from an ideally straight movement are required. A new drive concept consisting of a centrically acting eccentric drive for 100 nm positioning steps meets all industry requirements in terms of robustness, performance, reliability, integration and cost efficiency.

Unaffected by external vibrations for excellent, high-resolution images

|

|

|

|

|

|

Optionally expandable:

|

Highest reliability and stability

The measurement of the reached focus position is performed by a linear measuring system, if required also by an absolute one. This results in significantly increased accuracy and immediate availability of the system after switch-on. The eccentric drive realizes very small positioning steps and yet has an extremely stiff drive that is insensitive to external vibrations. Due to the high transmission ratio of the drive, even heavy optics can be used without any problems. The system, which is almost completely symmetrical with few compromises, offers unrivaled low guiding accuracy due to the diaphragm guides with rolling elements.

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle testsApplication areas

Confocal microscopy, laser scanning microscopy, LSCM, imaging technologies, laboratory automation, line scanners, benchtop laboratory instruments, camera systems, measuring instruments, cell monitoring, growth analysis, sensors and imaging systems for analytics, cancer research, in vitro diagnostics, high throughput screening, beam scanning

ID 219595 | Z | |

| Travel | [mm] | 2 |

| Repeatability unidirectional | [µm] | ± 0.1 |

| Repeatability bidirectional | [µm] | ± 0.5 |

| Positioning speed | [µm/s] | 100 |

| Max. load | [N] | 50 |

| Motor | Stepper Motor | |

| Drive | Eccentric, Gear Box | |

| Feedback | Linear Scale |