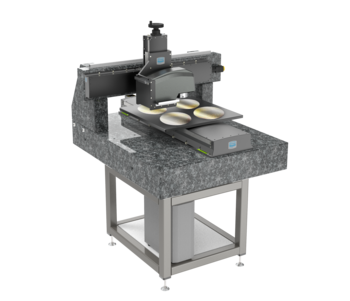

XYZ positioning system for automated inline wafer inspection e.g. layer thickness measurement | Stroke 650 x 650 x 100 mm

Inspection and Mikroscopy

782300:222.26

Automated XYZ inline wafer inspection with large sample capacity

This inspection system is specially designed for automated quality control of large and flat carrier up to 50 kg. The positioning system allows simultaneous positioning of sensor in Z and specimen in XY on a very compact footprint. The robust system also allows the use of heavy sensors or camera systems up to 20 kg in Z. The spindle drive, in combination with a spindle brake, guarantees optimum self-holding, so that a vertical position can be maintained in the de-energized state. The low-emission all-round enclosed system is also suitable for harsh industrial environments under dust and smoke. A suspension system has been attached to the granite for cable routing.

Compact design with optimized price/performance ratio

|

|

|

|

|

Optionally expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle testsFields of application

Automated inline inspection and microscopy of large samples e.g. wafers, chips, die, pins, bonding, printed circuit boards, solar cells, solar panels, laser, layer thickness measurement, AOI, quality assurance in dusty fuming environments, surface inspection, investigation of deposits, scratches, surface irregularities.

Verwendete Standard Komponenten

PLT165-SM

PLT240-SM