8-Axis Positioning System / Goniometer for inspection of displays | Fixture for swiveling sensors | Travels XY up to 100 mm, Z 230 mm

Inspection and Mikroscopy

782335:009.26

High-precision inspection of the smallest pixels from any angle

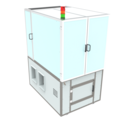

With this high-precision positioning system, the display to be inspected is moved on a XY stage to the customer-specific cameras or sensors. Both cameras / sensors can be swiveled and adjusted in height. In addition, the display under test can be aligned by tilting it parallel to the measuring surface in order to compensate for differences between the individual test objects. Due to the XY Rz positioning of the display, each pixel can thus be evaluated by the customized camera from any angle in the spatial radiation behavior.

Compact positioning solution with optimized price/performance ratio

|

|

|

|

Optionally expandable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle testsFields of application

Positioning system for high-precision inspection of e.g. flat panel displays, flexible electronic paper displays, visual quality assurance of displays, camera inspection systems, multi-axis display inspection, high-resolution computer-controlled display inspection

782335:009.26 | Rxj | Ryj | Rz | X | Y | Z | Ry1 | Ry2 | |

Standard System |

| JE310 | JE310 | DT310 | KDT310 | KDT310 | PLT240 | DT310 | DT310 |

[mm; deg] | ± 3 | ± 3 | 365 | 100 | 100 | 230 | ± 45 | ± 45 | |

Repeatability unidirectional | [µm; deg] | ± 0.006 | ± 0.006 | ± 0.005 | ± 2 | ± 2 | ± 3.9 | ± 0.005 | ± 0.005 |

Repeatability bidirectional | [µm; deg] | ± 0.01 | ± 0.01 | ± 0.007 | ± 2.5 | ± 2.5 | ± 4.4 | ± 0.007 | ± 0.007 |

[mm/s; deg/s] |

|

| 25 | 10 | 10 | 30 | 25 | 25 | |

| Max. speed | [mm/s; deg/s] | 50 | 20 | 20 | 60 | 50 | 50 | ||

Max. Load | [N] |

|

|

|

| 250 |

| 50 | 50 |

Motor |

| manual | manual | ||||||

Drive |

| Micrometer Head | Micrometer Head | Belt | Belt

| Belt

| |||

Guide |

|

| Thin section bearing | Profile rail

| Profile rail | Profile rail | Thin section bearing | Thin section bearing | |

Feedback |

|

| |||||||

| Length x width x height | [mm] | 500 x 940 x 810 (system) | 980 x 1400 x 1850 (system with rack and housing) | |||||||

Used Standard Components

DT310-SM

KDT310-SM

PLT240-SM

KGT 1214