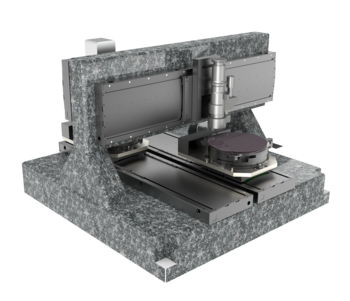

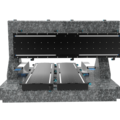

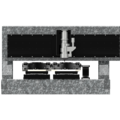

Doppel XYZ Wafer Positionierer für Scanner, Mikroskope und Wafer bis 12 inch / 300 mm (Reinraum ISO2) | Hub 720 x 720 x 100 mm

Inspektion und Mikroskopie

782430:002.26.oem

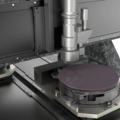

Hochdurchsatz-Screening von Wafern bis 12"

Das Inspektionssystem mit Verfahrwegen bis 720 mm erlaubt die gleichzeitige hochdynamische Prüfung mehrerer 300 mm / 6" Wafer. Das komplett betriebsbereite Achssystem, bestehend aus den Achsen, der Granitbasis mit Portal, dem Kabelmanagement und dem Motion Controller ist kundenspezifisch konfigurierbar.

Automatisierte Inspektion im 3-Schicht-Betrieb

|

|

|

|

Optional erweiterbar:

|

Individuelle Erweiterungen und Anpassungen

Die Engineering-Leistungen umfassen die Anpassung der Systeme an Ihre Struktur und die gewünschten Steuerungen oder die ganz Prototypen und passen die Systeme gerne an die Umgebungsanforderungen Ihrer Anwendung an, z.B. Partikelemission, Strahlung, Temperatur, Präzisions-Sonderteilefertigung, Arbeitshöhe, Kollisionsschutz, Sicherheitskonzept, Kompensationsfaktor und -filter, Sensorhalterung, Bremse, Entkopplung, Sonderschmierung, Sonderfarben, Halter, Adapter, Sondermotoren mit Pharmazulassung, Umfangreiche Dokumentationen, Testprotokoll, Lebensdauertests

Anwendungsfelder

Inspektion von Wafer und Masken bis 12 inch / 300 mm, Interferometrie und Metrologie, Mikroskopie, Materialprüfung, Probecards und Leiterplatten, AOI, Qualitätssicherung, Mikroskopie großer Probe, Oberflächenprüfung

| 782430:002.26 | X | Y | Z | |

| Standard System | PMT290-EDLM | PMT290-EDLM | ||

| Verfahrweg | [mm] | 720 | 720 | 100 |

| Wiederholgenauigkeit unidirektional | [µm] | ± 0.3 | ± 0.3 | ± 1.5 |

| Wiederholgenauigkeit bidirektional | [µm] | ± 0.7 | ± 0.7 | ± 2.5 |

| Positioniergeschwindigkeit | [mm/s] | 750 | 750 | 150 |

| Max. Geschwindigkeit | [mm/s] | 1500 | 1500 | 300 |

| Max. Last | [N] | 150 | 150 | ± 200 |

| Max. Probengröße | [Ø] | 12 inch / 300 mm | ||

| Länge x Breite x Höhe | [mm] | 1230 x 1200 x 1030 | ||

| Antrieb | Linearmotor | Linearmotor | Servomotor, Kugelgewindetrieb | |

| Motor | Dynamischer Linearmotor (eisenlos) | Dynamischer Linearmotor (eisenlos) | AC Servo | |

| Feedback | Linearmesssystem | Linearmesssystem | Motor-Encoder | |

| Reinraum Varianten | bis ISO Klasse 2 | |||

| Strahlung Varianten | auf Anfrage | |||