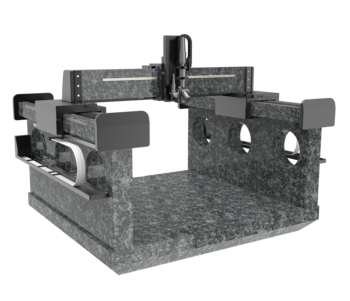

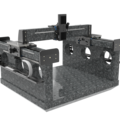

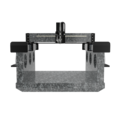

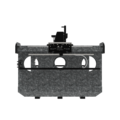

XYZ Gantry zur Inspektion großer Teile bis 450 x 1000 x 1000 mm | XY Linearmotor, Luftlager | Z Kugelgewindetrieb, DC-Motor

Gantries

782350:003.26

Ultrapräzises Vermessen von großen, hohen Teilen

Dieses XYZ Positioniersystem eignet sich für hochpräzise Vermessungen von großen und hohen Proben über 450 x 1000 x 1000 mm. Es wird ebenerdig aufgestellt, um ein Beladen mit Hubwagen zu ermöglichen.

An der Z-Achse kann ein kundenspezifisches Mikroskop, Kamera oder Sensor angebracht werden, um die Probe mit einer XYZ Überkopfbewegung zu vermessen. Damit werden hochauflösende Aufnahmen im Nanometer-Bereich sowie zahlreiche Messfunktionen für 2D- und 3D- Aufnahmen möglich.

Flexibel anpassbar auf individuelle Prozesse

|

|

|

|

|

Optional erweiterbar:

|

Individuelle Erweiterungen und Anpassungen

Die Engineering-Leistungen umfassen die Anpassung der Systeme an Ihre Struktur und die gewünschten Steuerungen. Darüber hinaus entwickeln wir Prototypen und passen die Systeme gerne an die Umgebungsanforderungen Ihrer Anwendung an, z.B. Partikelemission, Strahlung, Temperatur, Präzisions-Sonderteilefertigung, Arbeitshöhe, Kollisionsschutz, Sicherheitskonzept, Kompensationsfaktor und -filter, Sensorhalterung, Bremse, Entkopplung, Sonderschmierung, Sonderfarben, Halter, Adapter, Sondermotoren mit Pharmazulassung, Umfangreiche Dokumentationen, Testprotokoll, Lebensdauertests

Anwendungsfelder

Automatische optische Inspektion (AOI), 3D Aufnahmen, Inspektionssystem für Mess-und Prüfaufgaben, Lasermaterialaufgaben, Qualitätssicherung, Inspektion von großen sperrigen Objekten z.B. Motorblöcke

782350:003.26 | X | Y | Z | |

[mm] | 1000 | 1000 | 200 | |

[µm] | ± 0.3 | ± 0.3 | ± 0.3 | |

[µm] | ± 0.4 | ± 0.4 | ± 0.4 | |

[mm/s] | 1210 | 1210 | 30 | |

| Max. Geschwindigkeit | [mm/s] | 2420 | 2420 | 60 |

Max. Last | [N] | 100 | 500 | 150 |

Motor |

| |||

Antrieb |

|

|

| |

Führung | ||||

Feedback | ||||

| Max. Bauteilhöhe (Prüfling) | [mm] | 450 | ||

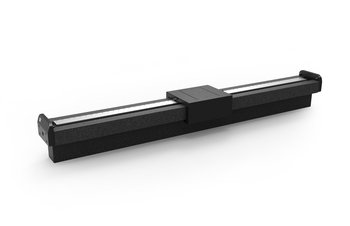

Verwendete Standard Komponenten

LA340-EDLM

PMT160-DC