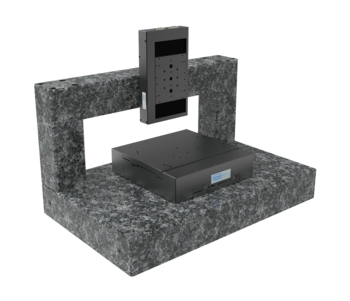

XYZ positioning system for high precision automated optical inspection | ball screw, cross roller, DC motor, linear measuring system

Combinations of laboratory axes

782300:130.26

Highly stable non-contact optical measurement in the submicrometer range

This 3-axis positioning system was developed for high-precision measuring applications in those cases where the XY stage moves the object being measured with extremely low pitch and yaw errors to the sensor or camera on the Z-axis. This is the case, for example, when measuring parts or recording 3D profiles even on tall parts. The XYZ system consists of the durable standard axes of the KT310 cross table and the PMT160 linear table on granite gantry.

Highly accurate and consistent measurement results

|

|

|

Flexibly configurable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we develop prototypes and like to adapt the systems to the environmental requirements of your application particle emission, radiation, temperature, precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, comprehensive documentation, test protocoll, llife cycle tests

Fields of application

Laboratory automation, AOI, capturing 3D profiles, 3-printing, surface inspection, inspection systems, tool measurement, coordinate metrology, micromachining or in optics

782300:130.26 | X | Y | Z | |

[mm; deg] | 200 | 200 | 50 | |

| Repeatability unidirectional | [µm; deg] | ± 0.5 | ± 0.5 | ± 0.3 |

Repeatability bidirectional | [µm; deg] | ± 0.7 | ± 0.7 | ± 0.4 |

| Positioning speed | [mm/s; deg/s] | 30 | 30 | 30 |

Max. load | [N] | 110 | 110 | 200 |

Motor |

| DC-Motor | DC-Motor | DC-Motor |

Drive |

| Ball Screw | ||

Feedback | Linear Scale | Linear Scale | Linear Scale |

Used Standard Components

PMT160-NM

PMT160-EDLM

KT310-DC

PMT160-DC

PMT160-SM

KT310-SM