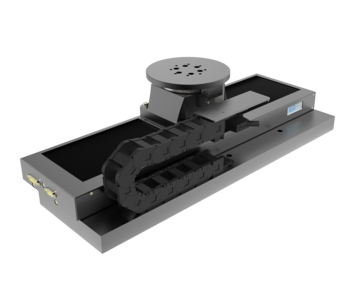

X Phi system for the positioning of optical lenses, cylinders e.g. stylus gauge | X DC motor, ball screw, cross roller, linear measuring system | Phi AC servo, angle measuring system

Combinations of laboratory axes

782300:212.26

Excellent stability for enormous resolutions

This X-Phi positioning system consists of high-precision and durable standard axes of the PMT160 linear stage and, for rotation, the DTS130-HM. It is ideal for measuring applications in which the specimen is moved precisely into measuring position and thus no additional feed axis is required.

Highly precise and reliable measurement results

|

|

|

|

Optionally configurable:

|

Individual extensions and customizations

Engineering services include the fitting of the systems to your structure and the desired controlls. Furthermore, we like to adapt the systems to the environmental requirements of your application e.g.: dust, radiation, temperature, Precision special parts manufacturing, working height, collision protection, safety concept, compensation factor and filter, sensor mounting, brake, decoupling, special lubrication, special colors, holders, adapters, special motors with pharmaceutical approval, test protocol, life tests

Fields application

Ideal for two-dimensional optical detection of roughness, structure mapping, surface structures, laboratory application, semiconductor inspection, optical inspection systems, quality assurance, motion system stylus gauge

| 782300:212.26 | X | Phi (Rz) | |

| Used standard component | PMT160-DC | DTS130-HM | |

| Travel | [mm; deg] | 135 | n x 360 |

Repeatability unidirectional | [µm; deg] | ± 1.9 | ± 0.0017 |

Repeatability bidirectional | [µm; deg] | ± 2.4 | ± 0.005 |

| Positioning speed | [mm/s, deg/s] | 10 | 50 |

Max. load | [N] | 150 | 74 |

Motor |

| ||

| Drive | Ball Screw | ||

| Feedback |

| Angular Scale |

Used Standard Components

PMT160-DC